Industry Knowledge

What are the common applications of Polycarbonate (PC) Granules in the manufacturing industry?

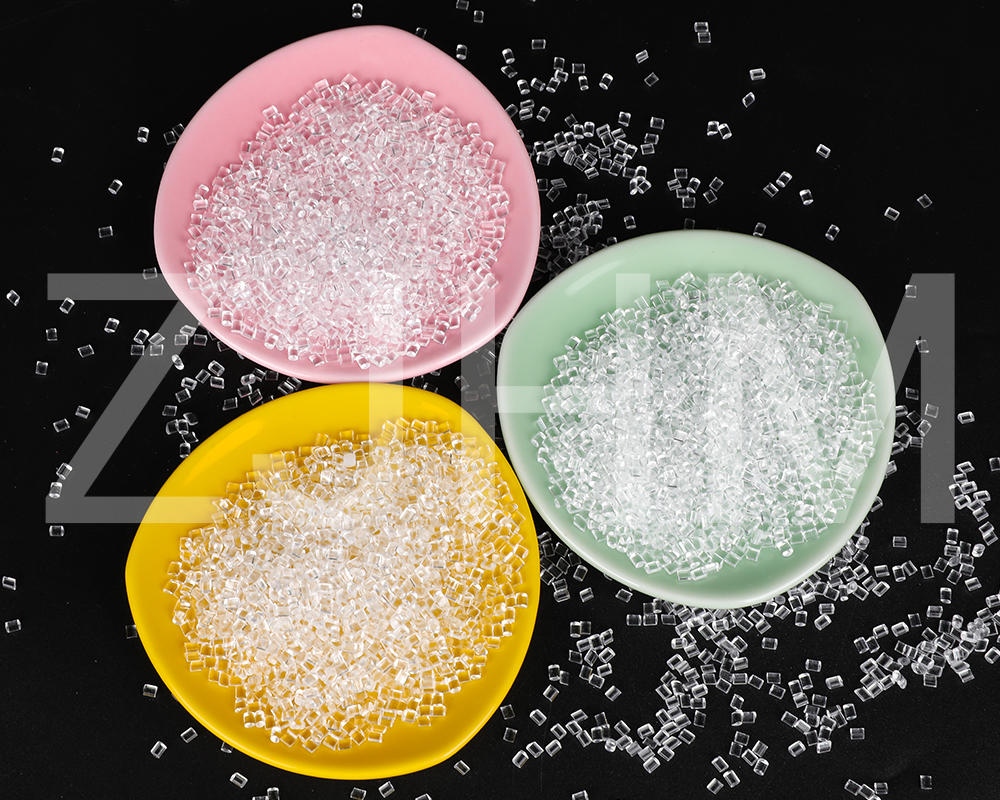

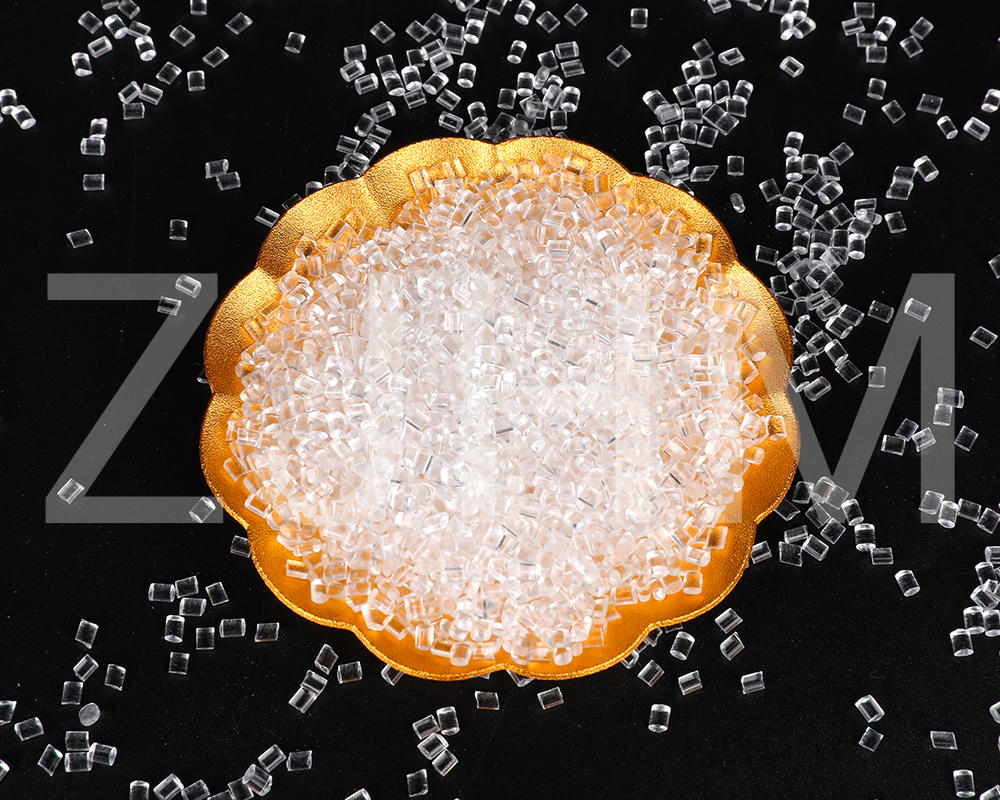

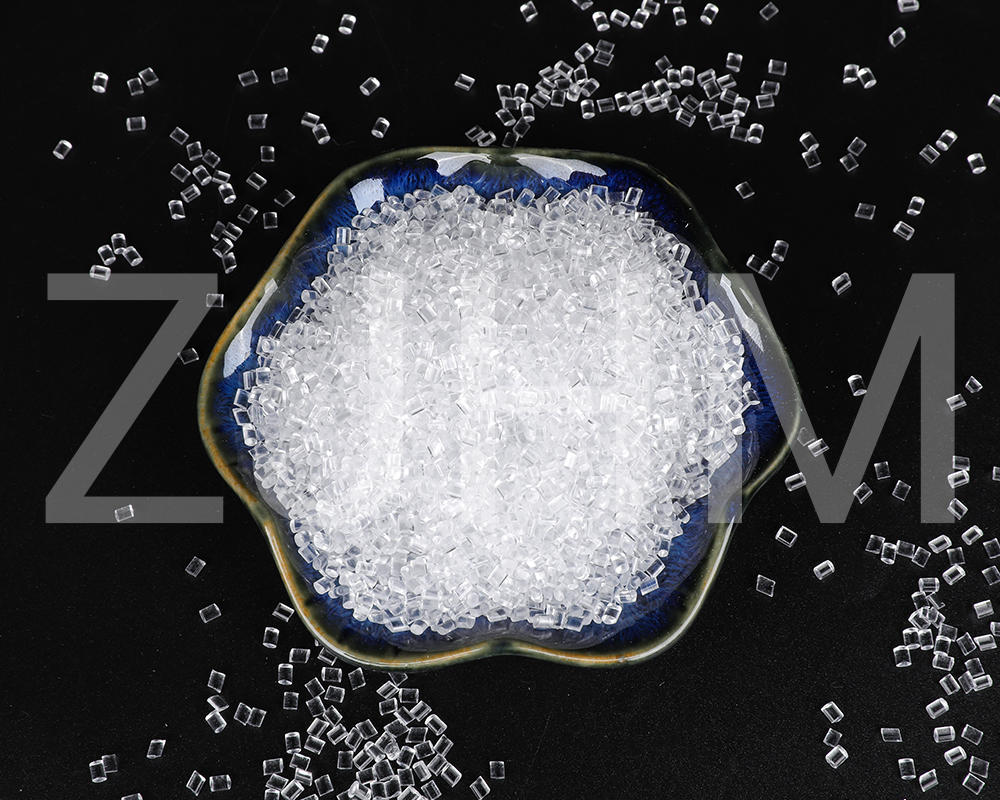

Polycarbonate (PC) granules are a type of thermoplastic polymer that are widely used in the manufacturing industry due to their unique properties. PC granules are known for their high strength, durability, and resistance to impact, making them an ideal material for a variety of applications.

One of the most common applications of PC granules is in the production of clear and tinted plastic sheets. These sheets are commonly used in the construction industry for glazing applications such as skylights, windows, and canopies. PC granules are preferred over other types of plastics for these applications because of their high impact resistance, UV resistance, and fire retardant properties.

Another common application of PC granules is in the production of automotive parts such as bumpers, dashboards, and headlights. PC granules are preferred for these applications because of their excellent impact resistance, high strength, and ability to withstand extreme temperatures. PC granules are also used in the production of automotive windows due to their superior clarity and scratch resistance.

PC granules are also used in the production of electronic components such as computer housings, mobile phone cases, and LED light fixtures. These applications require a high degree of impact resistance, heat resistance, and electrical insulation properties, all of which are provided by PC granules. Additionally, PC granules are preferred over other types of plastics for these applications because of their high clarity, which is essential for electronic displays and indicators.

The medical industry also uses PC granules in the production of medical devices and equipment. PC granules are ideal for these applications due to their high biocompatibility, sterilizability, and resistance to chemicals. Medical devices such as syringes, surgical instruments, and blood filters are commonly made from PC granules.

Another application of PC granules is in the production of sports equipment such as helmets, goggles, and protective gear. These applications require materials that can withstand high impacts and provide maximum protection to the user. PC granules are preferred for these applications due to their high impact resistance, durability, and ability to withstand extreme temperatures.

How does the manufacturing process of Polycarbonate (PC) Granules differ from other plastic materials?

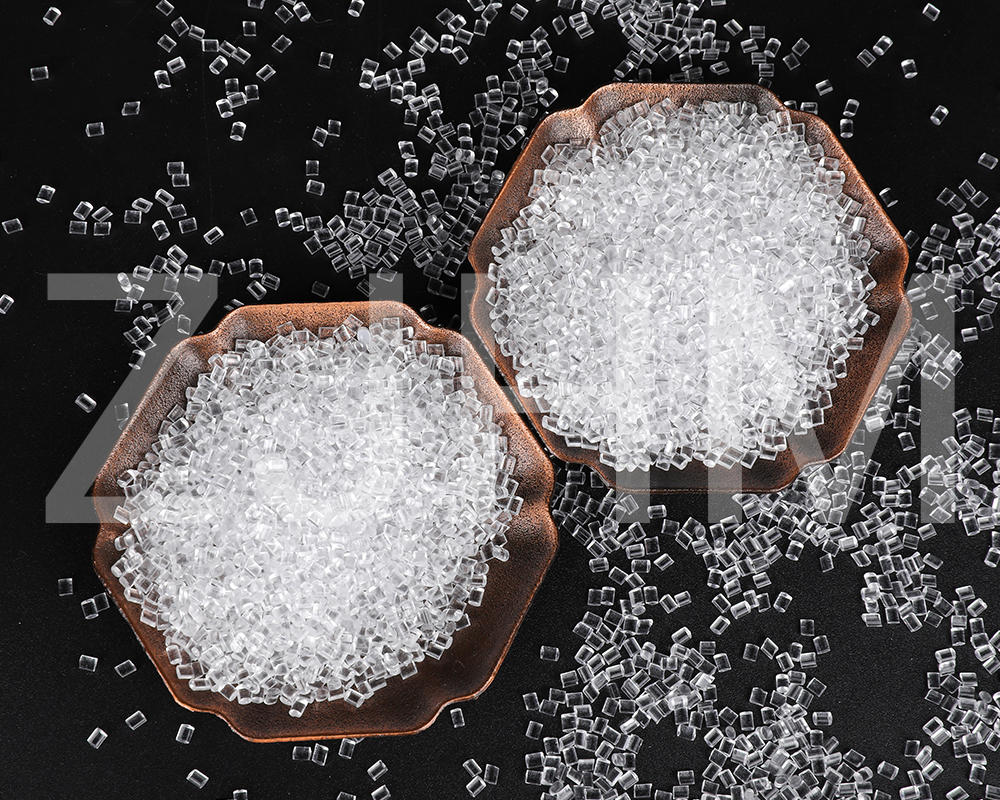

Polycarbonate (PC) is a thermoplastic polymer that is widely used in various industries due to its exceptional properties. It is a strong, lightweight, and transparent material that can withstand high temperatures and impact. PC is commonly used in the production of eyeglasses, automotive parts, electronics, and other consumer products. The manufacturing process of PC granules differs from other plastic materials due to its unique chemical properties and processing requirements.

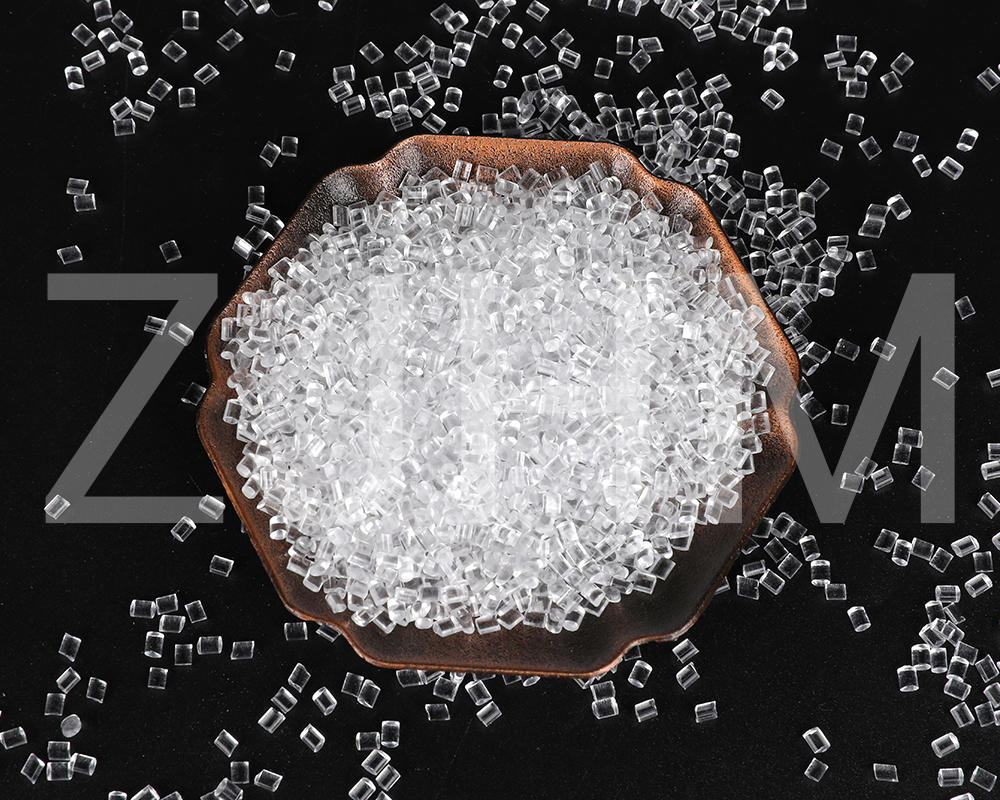

The first step in the manufacturing process of PC granules is the production of bisphenol-A (BPA). BPA is the primary raw material used in the production of PC. BPA is synthesized by the condensation of phenol and acetone. The BPA is then polymerized to form PC. The polymerization process involves heating the BPA under high pressure in the presence of a catalyst. The polymerization reaction is exothermic and releases heat, which must be controlled to prevent thermal degradation of the polymer.

Once the PC polymer is formed, it is extruded into granules. Extrusion is the process of forcing the PC polymer through a die to form a continuous shape. The extruded PC is then cooled and cut into granules. The granules are then washed and dried to remove any impurities and moisture.

The manufacturing process of PC granules differs from other plastic materials due to the unique properties of PC. PC is a high-temperature thermoplastic that requires careful control of the processing temperature to prevent thermal degradation. PC also has a high viscosity, which makes it difficult to process compared to other plastic materials. The processing equipment used for PC must be designed to handle the high temperatures and pressures required for the polymerization and extrusion process.

English

English

Español

Español