Industry Knowledge

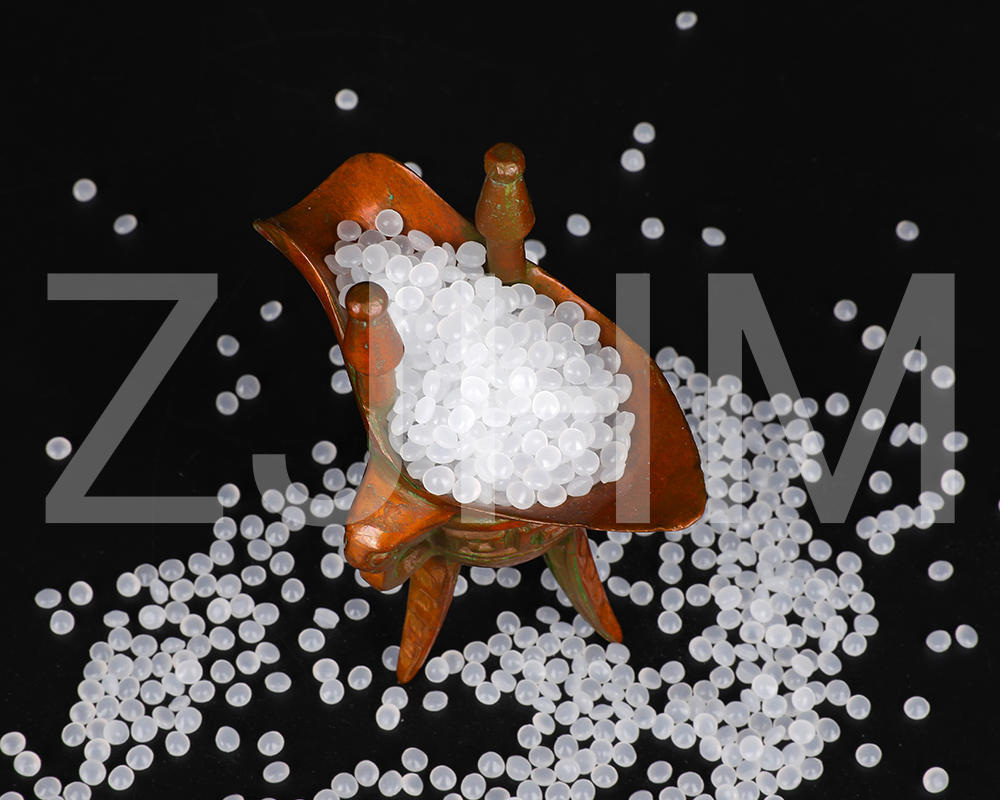

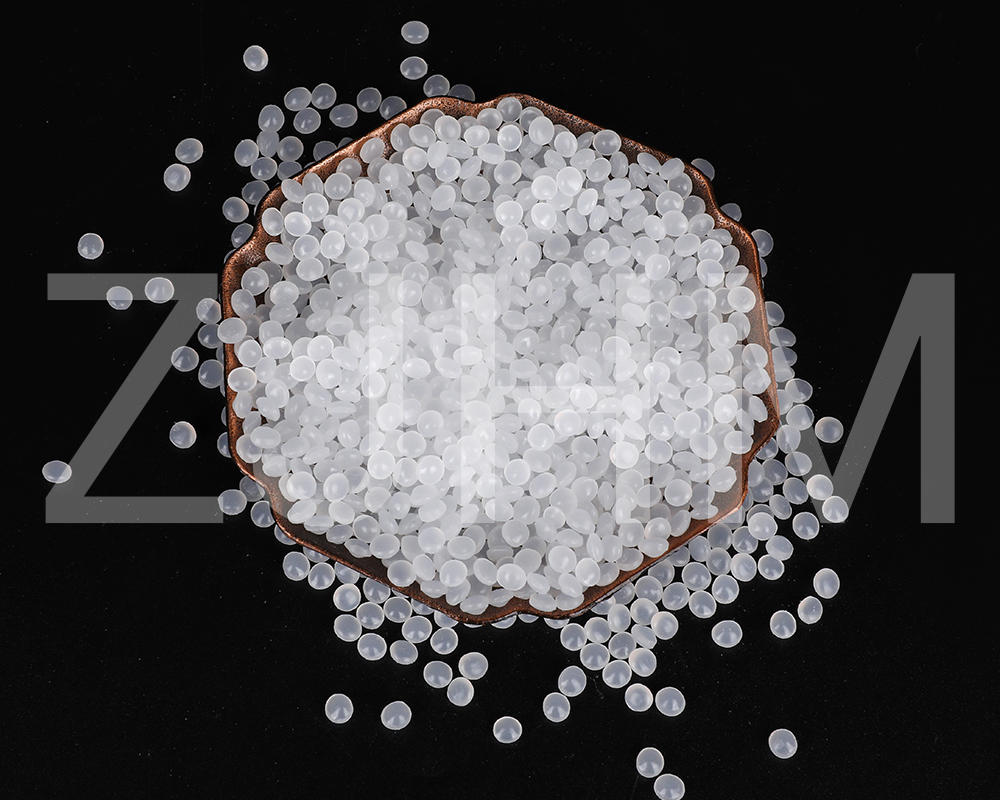

What are LLDPE granules and how are they produced?

Linear low-density polyethylene (LLDPE) granules are a type of thermoplastic polymer that is widely used in various industries for the manufacturing of a diverse range of products. LLDPE granules are known for their high tensile strength, toughness, flexibility, and resistance to impact and puncture.

LLDPE granules are produced by the polymerization of ethylene using a Ziegler-Natta catalyst system. The process involves the use of a high-pressure reactor, where ethylene gas is compressed and heated to initiate the polymerization reaction. The catalyst system is then added to the reactor, which helps to control the rate of the reaction and the molecular weight of the resulting polymer.

During the polymerization process, the ethylene molecules are bonded together to form a long chain of polyethylene molecules. The molecular structure of LLDPE is different from that of other types of polyethylene, such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE), due to the presence of short-chain branches in the polymer chain. These branches are created by the incorporation of a comonomer, such as 1-butene or 1-hexene, into the reaction mixture. The addition of comonomer leads to the formation of short branches that disrupt the regular structure of the polymer chain and give LLDPE its unique properties.

The polymerization process is typically carried out at high pressures and temperatures, ranging from 150 to 350 °C and 1000 to 3000 bar. The reaction time can vary depending on the desired properties of the LLDPE granules and the type of reactor used. After the polymerization is complete, the LLDPE resin is cooled and solidified into pellets or granules, which can then be further processed into finished products.

The production of LLDPE granules requires careful control of the reaction parameters, such as temperature, pressure, and catalyst concentration, to ensure that the resulting polymer has the desired properties. The molecular weight distribution of the polymer is also an important factor that affects the properties of the LLDPE granules. By controlling the molecular weight distribution, manufacturers can tailor the properties of LLDPE granules for specific applications, such as film extrusion, blow molding, and injection molding.

What are the different grades of LLDPE granules available in the market?

The different grades of LLDPE granules available in the market can be broadly categorized into three types:

Low Density LLDPE (LDPE)

Medium Density LLDPE (MDPE)

High Density LLDPE (HDPE)

Low Density LLDPE (LDPE) is the softest and most flexible grade of LLDPE granules. It is commonly used in the production of thin films, such as those used in grocery bags, sandwich bags, and other similar products. LDPE has excellent clarity and is very resistant to water and chemicals, making it ideal for use in packaging applications where the contents need to be visible and protected.

Medium Density LLDPE (MDPE) is a grade of LLDPE granules that is slightly stiffer than LDPE. It has a higher density and greater strength, making it suitable for use in more heavy-duty applications. MDPE is commonly used in the production of thicker films and bags, such as those used for trash and recycling, as well as in the production of tubing, injection-molded parts, and other similar products.

High Density LLDPE (HDPE) is the stiffest and most rigid grade of LLDPE granules. It has the highest density and strength, making it ideal for use in applications where toughness and durability are critical. HDPE is commonly used in the production of blow-molded bottles, drums, and containers, as well as in the production of pipes and fittings, and other similar products.

In addition to these three broad categories, there are also specialized grades of LLDPE granules available in the market that are designed for specific applications. For example, there are grades of LLDPE granules that are specifically designed for use in the production of films and sheets with enhanced tear resistance, puncture resistance, or slip resistance. There are also grades of LLDPE granules that are designed for use in injection molding applications, such as those used in the production of toys, housewares, and automotive components.

The choice of LLDPE grade depends on the specific requirements of the application. Factors such as the desired flexibility, strength, clarity, and chemical resistance of the final product, as well as the manufacturing process and equipment, will all influence the choice of LLDPE grade. It is important to choose the right grade of LLDPE granules to ensure that the final product meets the desired specifications and performs as expected.

English

English

Español

Español