Industry Knowledge

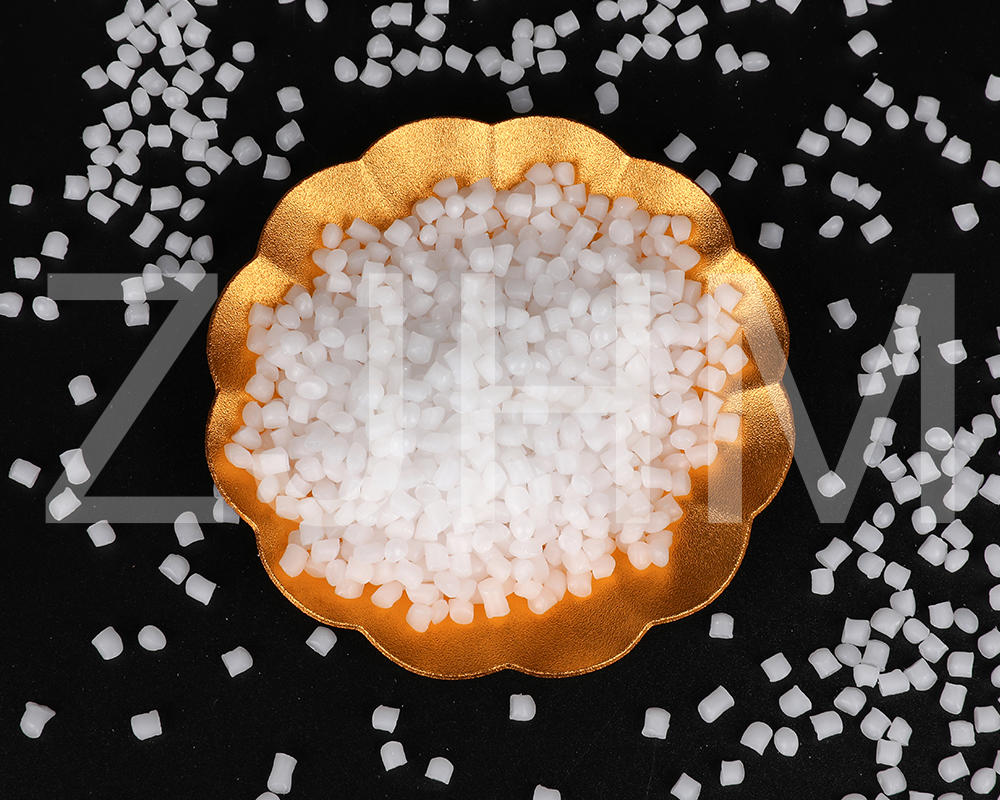

What are the main properties of polypropylene granules, and how do they compare to other plastics?

Polypropylene (PP) is a thermoplastic polymer that has become increasingly popular in a wide range of applications due to its unique properties. It is a highly versatile material that is used in a variety of products, from automotive components and medical devices to food packaging and consumer goods.

One of the key properties of polypropylene granules is their excellent chemical resistance. They are highly resistant to many acids, bases, and solvents, making them an ideal choice for a range of industrial and commercial applications. Additionally, polypropylene is highly resistant to UV radiation and does not degrade easily when exposed to sunlight.

Another important property of polypropylene is its excellent mechanical strength. Polypropylene granules are highly durable and can withstand a range of physical stresses, making them ideal for use in products that are subjected to high levels of wear and tear. They also have a high tensile strength and can withstand large amounts of stress without breaking.

In addition to their excellent chemical and mechanical properties, polypropylene granules are also highly resistant to moisture and are not easily affected by changes in temperature. They are highly stable and do not easily degrade, making them an ideal choice for products that are exposed to harsh environmental conditions.

Compared to other plastics, polypropylene has several distinct advantages. For example, it has a lower density than many other plastics, making it lighter and more cost-effective to transport. Additionally, it is highly resistant to fatigue, which means it can withstand repeated stress without cracking or breaking.

What are some common applications of polypropylene granules in the manufacturing industry?

One of the most common applications of polypropylene granules is in the packaging industry. The granules are used to produce various types of packaging materials such as bags, pouches, and containers. These products are popular due to their durability, flexibility, and ability to withstand extreme temperatures. Polypropylene packaging is commonly used for food products, household items, and industrial goods.

In the textile industry, polypropylene granules are used to produce non-woven fabrics. Non-woven fabrics are created by bonding fibers together through heat, pressure, or chemicals, without weaving or knitting them. These fabrics are commonly used in applications such as medical clothing, hygiene products, geotextiles, and home furnishings. Polypropylene non-woven fabrics are lightweight, breathable, and water-resistant, making them an ideal choice for a variety of applications.

Another common application of polypropylene granules is in the automotive industry. The granules are used to produce various components such as bumpers, dashboard parts, and door panels. Polypropylene is used in the automotive industry due to its lightweight, impact resistance, and ability to withstand extreme temperatures. These properties make it an ideal material for creating durable and long-lasting automotive components.

Polypropylene granules are also used in the construction industry. The granules are used to produce pipes, fittings, and other components for plumbing and heating systems. Polypropylene pipes and fittings are popular due to their resistance to chemicals, abrasion, and high temperatures. Additionally, they are lightweight, making them easy to handle and install.

In the medical industry, polypropylene granules are used to produce various medical devices and equipment such as syringes, catheters, and IV bags. Polypropylene is an ideal material for medical applications due to its biocompatibility, sterilization capabilities, and resistance to chemicals. These properties make it a popular choice for creating medical products that are safe, reliable, and long-lasting.

How are polypropylene granules produced, and what is the process for manufacturing them?

Polypropylene granules are typically produced using a process called polymerization. Polymerization is the chemical process of combining monomers, which are small molecules, into long-chain polymers. In the case of polypropylene, the monomer used is propylene. Propylene is a gas that is derived from crude oil and natural gas.

The polymerization process for polypropylene granules is typically carried out using two different methods: suspension polymerization and gas-phase polymerization. In suspension polymerization, the monomer is suspended in water and a catalyst is added to initiate the reaction. The reaction takes place in a reactor vessel that is constantly agitated to ensure that the monomer is evenly distributed throughout the water. As the reaction progresses, the monomer particles stick together and form small granules. The resulting polypropylene granules are then separated from the water, washed, and dried.

In gas-phase polymerization, the monomer is vaporized and fed into a reactor vessel along with a catalyst. The reaction takes place in the gas phase, and the resulting polypropylene granules are formed on the surface of a fluidized bed. The fluidized bed consists of small beads that are suspended in air and constantly agitated. The beads act as a support for the growing granules, which eventually become dense enough to be separated from the bed. The resulting polypropylene granules are then cooled, separated from the catalyst, and packaged for shipment.

English

English

Español

Español