Industry Knowledge

What is the chemical composition of Polystyrene (GPPS) Granules?

Polystyrene (PS) is a thermoplastic polymer that is widely used in a variety of applications due to its unique properties, such as high stiffness, clarity, and impact resistance. Polystyrene is made up of a repeating unit of styrene monomers, which are linked together through a process called polymerization. There are several different types of polystyrene, including general purpose polystyrene (GPPS), high impact polystyrene (HIPS), and expandable polystyrene (EPS).

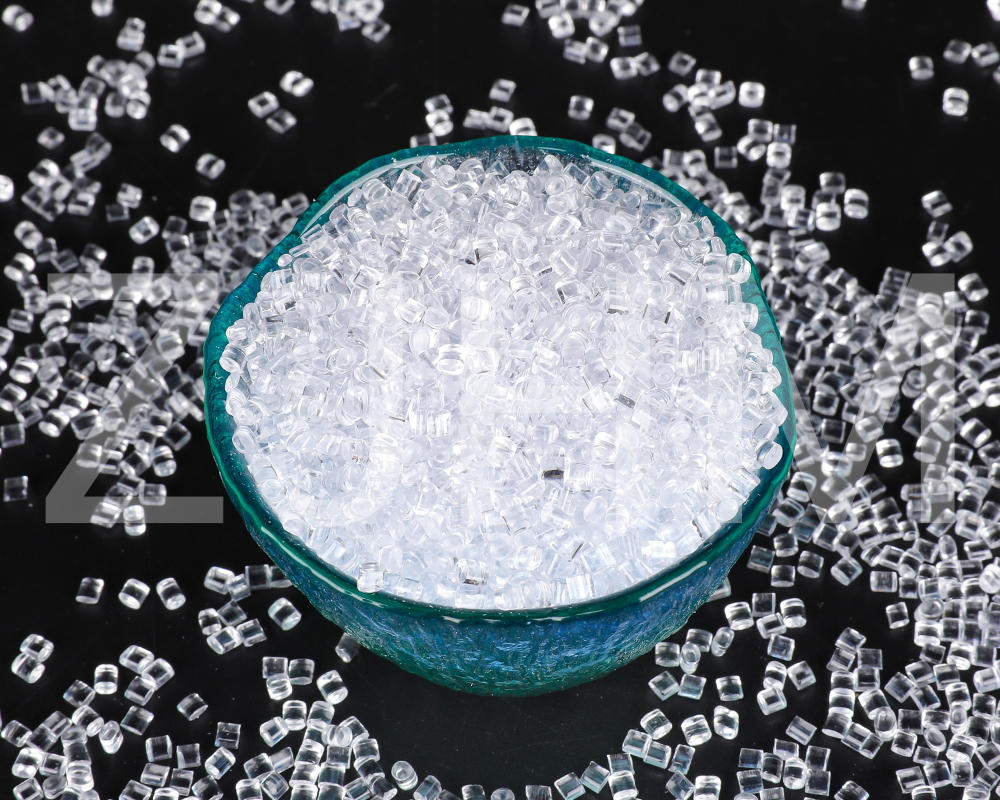

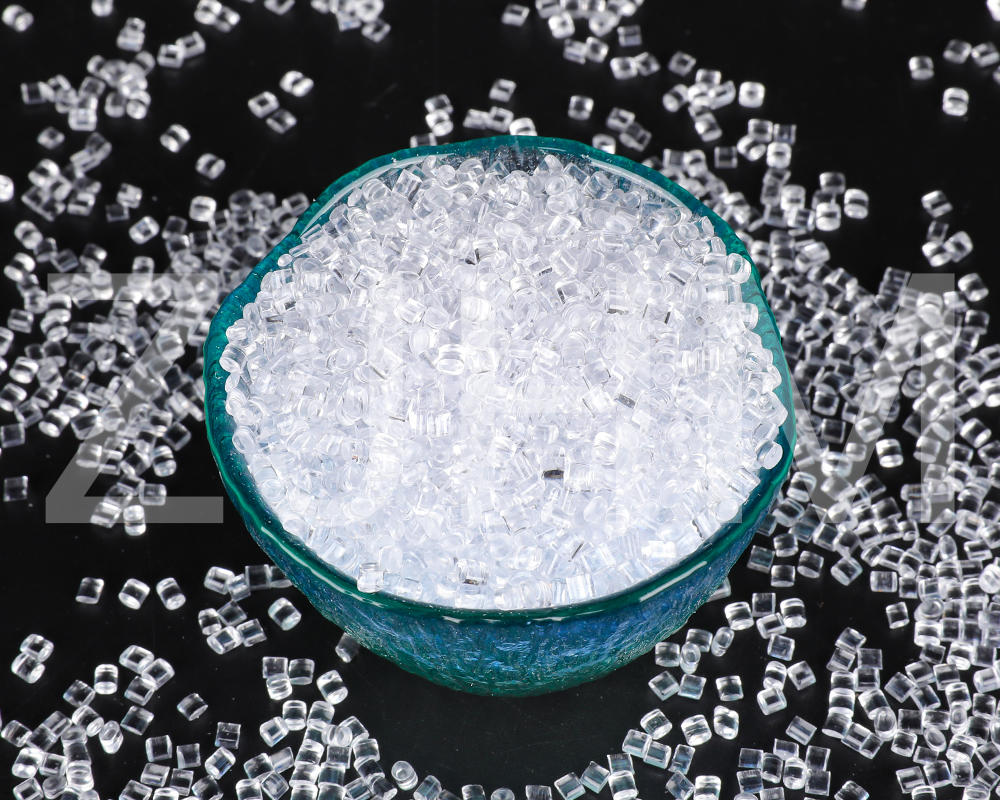

GPPS is a type of polystyrene that is commonly used in applications such as food packaging, consumer goods, and toys. GPPS is a transparent, rigid material that is easy to process and has good dimensional stability. It is also relatively inexpensive, making it an attractive option for a wide range of applications.

The chemical composition of GPPS granules is relatively simple. GPPS is composed of polystyrene chains that are made up of repeating units of styrene monomers. Styrene is an organic compound that is produced from benzene and ethylene. The chemical formula for styrene is C8H8, and its molecular weight is 104.15 g/mol.

During the polymerization process, styrene monomers are linked together through a chemical reaction known as addition polymerization. In this process, the double bond between the carbon atoms in the styrene monomer is broken, and the resulting free radicals react with other styrene monomers to form long chains. The polymerization reaction is typically initiated using a catalyst, such as a peroxide or a metal salt.

The resulting polystyrene chains are relatively straight and rigid, which gives GPPS its characteristic properties. GPPS is a transparent material because the polystyrene chains are closely packed together, which allows light to pass through with minimal scattering. GPPS is also a relatively hard and brittle material, which makes it ideal for applications that require high stiffness and dimensional stability.

In addition to styrene monomers, GPPS granules may also contain small amounts of other additives, such as colorants, stabilizers, and processing aids. These additives are typically added to improve the performance or processing characteristics of the material.

How are Polystyrene (GPPS) Granules produced?

Polystyrene (PS) is a widely used thermoplastic material that is known for its versatility and cost-effectiveness. It is used in a variety of applications ranging from packaging materials to consumer goods. General Purpose Polystyrene (GPPS) is one of the most common forms of polystyrene, which is used extensively in the manufacturing industry. GPPS is a transparent, rigid and brittle material that is produced in the form of granules.

The production process of Polystyrene (GPPS) granules involves several steps that transform raw materials into finished products. The process starts with the conversion of styrene monomer into polystyrene polymer. The polymerization reaction is initiated by a catalyst, and it takes place in a reactor vessel under high temperature and pressure. The reaction produces a viscous solution of polystyrene, which is then cooled and solidified into a granular form.

The next step involves the purification of the polystyrene granules. This is done to remove any impurities or residual monomer that may be present in the granules. The granules are washed with a solvent such as hexane or acetone to remove any residual monomer. The purified granules are then dried to remove any residual solvent.

The final step involves the addition of various additives and colorants to the polystyrene granules. The additives and colorants are added in precise amounts to achieve the desired properties and color of the final product. The granules are mixed with the additives and colorants in a mixer, and the mixture is heated to melt the granules. The molten mixture is then extruded into the desired shape or molded into the desired product.

The production of Polystyrene (GPPS) granules is a highly automated process that is carried out in large-scale production facilities. The process is tightly controlled to ensure consistency and quality of the final product. The granules are produced in various sizes and shapes to meet the specific requirements of different applications.

What are the different applications of Polystyrene (GPPS) Granules in industries?

Polystyrene (GPPS) granules are a widely used material in various industries due to their versatile properties. Polystyrene is a synthetic polymer made from styrene monomers, which can be produced in various grades, including general-purpose polystyrene (GPPS) and high-impact polystyrene (HIPS). GPPS is a thermoplastic material that has excellent transparency, rigidity, and processability.

One of the most significant applications of GPPS granules is in the packaging industry. Due to their clarity and rigidity, they are commonly used to make food containers, cosmetic packaging, and disposable cups and plates. They can also be formed into various shapes, making them suitable for custom packaging requirements. Moreover, GPPS granules can be easily processed using various manufacturing techniques such as injection molding, thermoforming, and extrusion, making them a popular choice for packaging manufacturers.

In addition to the packaging industry, GPPS granules are also used in the production of consumer goods. These include toys, household appliances, and electronic components. The granules can be molded into complex shapes, making them ideal for the production of intricate parts. The excellent finish and gloss of GPPS make it an attractive choice for such applications, providing a sleek and shiny surface.

The construction industry is another significant consumer of GPPS granules. They are used in the production of insulation boards, paneling, and other materials. The lightweight and insulating properties of GPPS make it an ideal choice for insulation applications. GPPS is also used in the production of lighting fixtures and lampshades. The high transparency of GPPS granules allows for maximum light transmission, making it a popular choice for these applications.

GPPS granules are also commonly used in the automotive industry. They are used to produce interior and exterior components, such as dashboards, door panels, and trims. GPPS is lightweight, durable, and can be formed into complex shapes, making it an ideal choice for such applications. Additionally, GPPS is resistant to heat and chemicals, making it suitable for use in harsh environments.

English

English

Español

Español