Industry Knowledge

How is the demand for LDPE granules affected by changing consumer preferences and behaviors?

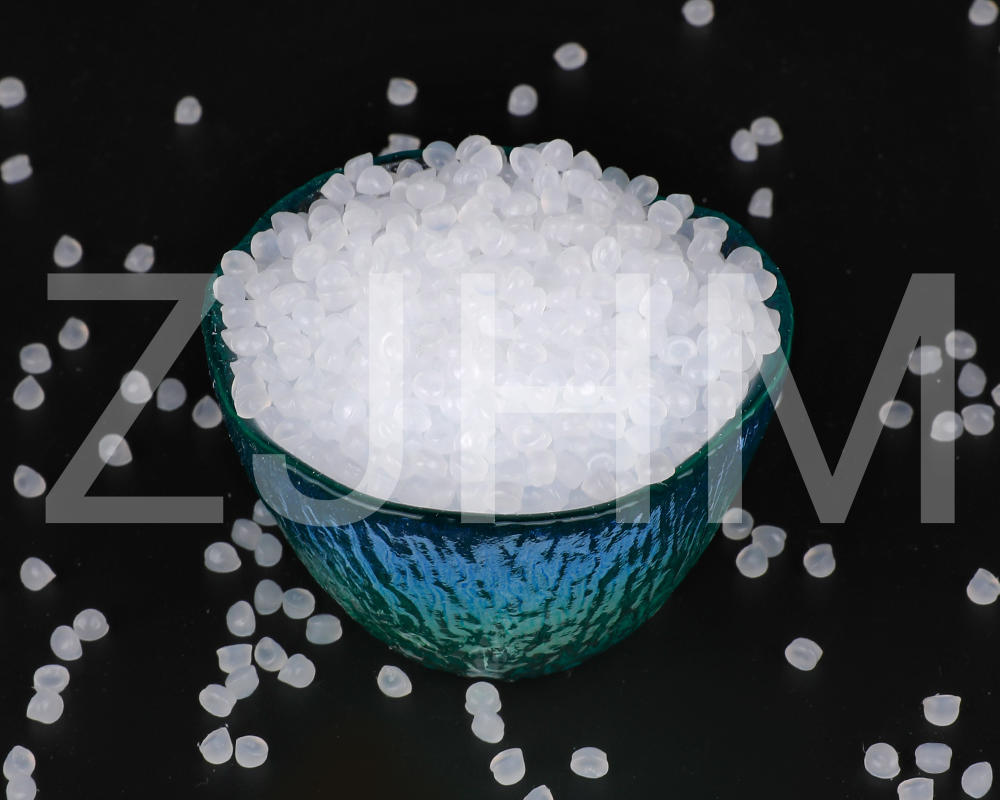

Low-density polyethylene (LDPE) granules are a type of thermoplastic that are widely used in various industries. LDPE granules are valued for their flexibility, toughness, and transparency, which makes them an ideal material for manufacturing products such as plastic bags, packaging films, and even medical equipment.

However, the demand for LDPE granules is not just determined by the growth of industries that use it as a raw material. Consumer preferences and behaviors also play a crucial role in shaping the demand for LDPE granules. As consumers become more conscious about the environmental impact of their purchases, they are starting to make different choices that could affect the demand for LDPE granules.

One factor that is affecting consumer preferences is the growing awareness about plastic pollution. Plastic waste has become a major environmental issue, with millions of tons of plastic entering the oceans and harming marine life every year. Consumers are becoming more aware of the impact of plastic waste and are starting to seek out products that are more environmentally friendly. This has led to a shift towards products made from biodegradable or recycled materials, which could potentially reduce the demand for LDPE granules.

Another factor that is shaping consumer preferences is the growing interest in sustainable living. As more people become concerned about the impact of their lifestyles on the environment, they are looking for products that are more sustainable and eco-friendly. This has led to a rise in demand for products that are made from renewable resources, such as bamboo or cornstarch. While LDPE granules are not inherently unsustainable, the perception that they are made from non-renewable resources could potentially lead to a decline in demand.

What are the technological advancements in the production of LDPE granules and how do they impact the industry?

Low-density polyethylene (LDPE) is a versatile plastic material that is widely used in various applications, such as packaging, agriculture, construction, and healthcare. LDPE granules are the raw materials used for manufacturing LDPE products, and the production process of these granules has undergone significant technological advancements in recent years. These advancements have resulted in improved product quality, increased efficiency, and reduced environmental impact, among other benefits.

One of the most significant technological advancements in the production of LDPE granules is the development of new catalysts. Catalysts are essential components in the production process of LDPE, as they promote the polymerization of ethylene to form LDPE. In recent years, researchers have developed new catalysts that can produce LDPE granules with higher molecular weight and more uniform properties. These new catalysts also allow for better control over the polymerization process, resulting in a higher yield of LDPE granules.

Another technological advancement in the production of LDPE granules is the use of advanced reactor designs. Reactors are the vessels where the polymerization process takes place, and advancements in reactor design have resulted in more efficient and effective production of LDPE granules. For example, some reactor designs allow for better control over the reaction conditions, resulting in a more consistent product quality. Other reactor designs enable the production of LDPE granules with specific properties, such as improved flexibility or higher tensile strength.

The use of advanced process control systems is another technological advancement in the production of LDPE granules. Process control systems are computer-based systems that monitor and control various aspects of the production process, such as temperature, pressure, and flow rates. These systems can detect and correct process deviations in real-time, resulting in more consistent product quality and reduced waste. Process control systems also allow for better process optimization, resulting in increased efficiency and reduced production costs.

What is the competitive landscape of the LDPE granules market and who are the key players?

Low-density polyethylene (LDPE) granules are widely used in the manufacturing of various plastic products due to their excellent properties, such as high flexibility, toughness, and transparency. The global LDPE granules market is highly competitive and has been witnessing significant growth in recent years, driven by the increasing demand for LDPE granules in various industries, including packaging, construction, and automotive.

The competitive landscape of the LDPE granules market is dominated by several key players who account for a significant share of the market.

The LDPE granules market is highly fragmented, with several players operating in the market. The market is expected to witness significant growth in the coming years, driven by the increasing demand for LDPE granules in various end-use industries, such as packaging, construction, and automotive. The players in the market are focused on expanding their product portfolio, investing in research and development activities, and forming strategic partnerships and collaborations to strengthen their market position and gain a competitive edge.

English

English

Español

Español