Industry Knowledge

What are the primary applications of HIPS granules in the plastic industry?

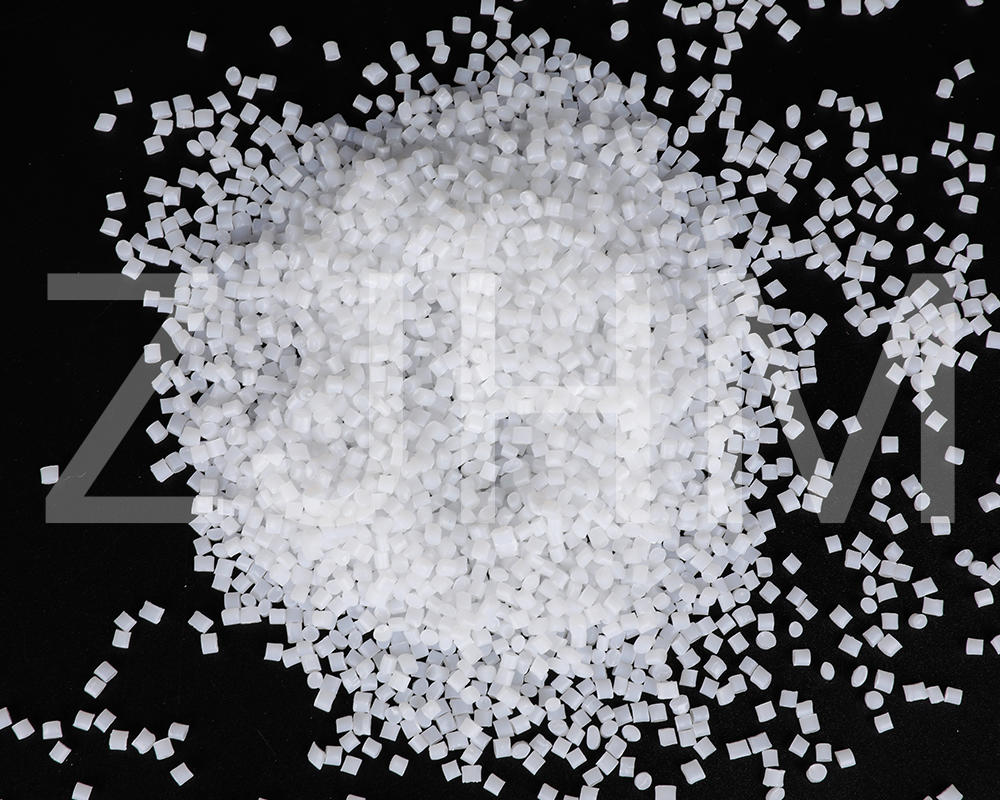

High Impact Polystyrene (HIPS) granules are a type of plastic material that has gained significant popularity in the plastic industry. These granules are derived from polystyrene, a thermoplastic material that is commonly used in manufacturing different types of plastic products.

The primary applications of HIPS granules in the plastic industry are diverse and wide-ranging. One of the most common uses of HIPS granules is in the manufacturing of consumer goods such as electronic products, toys, and packaging materials. HIPS granules are particularly popular in the production of computer and electronic device casings, which require high impact resistance to protect delicate internal components from damage.

Another major application of HIPS granules is in the automotive industry, where the granules are used in the production of various parts such as bumpers, interior trim, and dashboards. HIPS granules are preferred in this industry due to their exceptional toughness, dimensional stability, and resistance to heat and chemicals. Additionally, HIPS granules are also used in the construction industry, where they are used to manufacture window frames, door frames, and other building components that require high impact resistance and dimensional stability.

In the food and beverage industry, HIPS granules are commonly used to produce disposable cups, plates, and utensils. HIPS granules are preferred in this industry due to their excellent clarity and ability to retain the shape of molded products, even under high temperatures. HIPS granules are also highly suitable for the manufacture of food packaging materials due to their high chemical resistance, which helps to prevent contamination of packaged products.

HIPS granules are also widely used in the healthcare industry, where they are used in the manufacture of various medical devices and equipment. These granules are highly suitable for this industry due to their biocompatibility, which means they do not react with human tissue or bodily fluids. HIPS granules are also resistant to moisture, chemicals, and other environmental factors that may compromise the quality and safety of medical products.

How does the molecular structure of HIPS granules affect their mechanical properties?

Polymers are widely used in various applications due to their excellent mechanical and physical properties, ease of processing, and low cost. High Impact Polystyrene (HIPS) is a commonly used polymer that is used in a wide range of applications such as packaging, consumer goods, and building materials. HIPS is a blend of polystyrene and polybutadiene, where the polybutadiene acts as a rubber modifier to improve the toughness and impact resistance of the material.

The mechanical properties of HIPS, such as its tensile strength, elongation at break, and impact strength, are influenced by a variety of factors including the molecular structure of the polymer. HIPS granules are commonly used in injection molding processes to produce various parts and components. Therefore, understanding how the molecular structure of HIPS granules affects their mechanical properties is of great importance in the polymer industry.

The molecular structure of HIPS granules is mainly determined by the polymerization process used to synthesize the material. The polymerization process can influence the molecular weight, molecular weight distribution, and polymer morphology of the material. For example, the use of different initiators or reaction conditions can result in different molecular weights or molecular weight distributions of the polymer chains. The presence of different additives or comonomers can also affect the polymer morphology, such as the size and distribution of the polybutadiene domains in the HIPS blend.

The molecular weight of the polymer chains is known to affect the mechanical properties of polymers. In general, an increase in molecular weight can lead to an increase in tensile strength and modulus, but a decrease in elongation at break and impact strength. This is because higher molecular weight polymers have stronger intermolecular forces and can resist deformation more effectively, but are less flexible and prone to fracture under impact loading. Therefore, controlling the molecular weight of HIPS granules is important for achieving the desired balance of mechanical properties.

The molecular weight distribution (MWD) of HIPS granules can also impact the mechanical properties of the material. A broad MWD can result in a material with a wider range of molecular weights and chain entanglements, which can lead to improved toughness and impact strength. On the other hand, a narrow MWD can lead to a material with more uniform properties, but with reduced toughness and impact resistance. Therefore, optimizing the MWD of HIPS granules is important for achieving the desired mechanical properties.

What are the advantages of using HIPS granules in injection molding applications?

Injection molding is a widely used manufacturing process that involves the injection of molten material into a mold cavity to create a desired shape or form. Polymers are commonly used in injection molding applications due to their ease of processing, low cost, and excellent mechanical and physical properties. High Impact Polystyrene (HIPS) is a commonly used polymer in injection molding applications due to its unique combination of properties.

HIPS is a blend of polystyrene and polybutadiene, where the polybutadiene acts as a rubber modifier to improve the toughness and impact resistance of the material. The use of HIPS granules in injection molding applications offers a number of advantages compared to other polymers.

One of the major advantages of using HIPS granules in injection molding applications is their ease of processing. HIPS granules have a relatively low melting point and can be easily melted and molded into complex shapes with high precision. The material also has a low viscosity, which allows for easy flow through the injection molding machine and into the mold cavity. This makes HIPS a preferred choice for injection molding applications where high volumes of parts need to be produced quickly and efficiently.

Another advantage of using HIPS granules in injection molding applications is their excellent mechanical properties. HIPS has a high tensile strength and good dimensional stability, which makes it ideal for producing parts that require high strength and precision. The material also has excellent impact resistance, which makes it ideal for producing parts that need to withstand high levels of stress and strain.

HIPS granules are also highly versatile and can be easily modified to suit specific applications. The addition of various additives or fillers can improve the properties of HIPS, such as its flame retardancy, chemical resistance, or electrical conductivity. This makes HIPS granules a preferred choice for a wide range of applications, such as automotive parts, toys, household appliances, and packaging.

HIPS granules also offer a cost-effective solution for injection molding applications. The material is widely available and relatively inexpensive compared to other polymers. This makes HIPS granules a preferred choice for producing high volumes of parts that require good mechanical properties at a reasonable cost.

English

English

Español

Español