Industry Knowledge

What are the primary uses of Ethylene Vinyl Acetate (EVA) granules in the manufacturing industry?

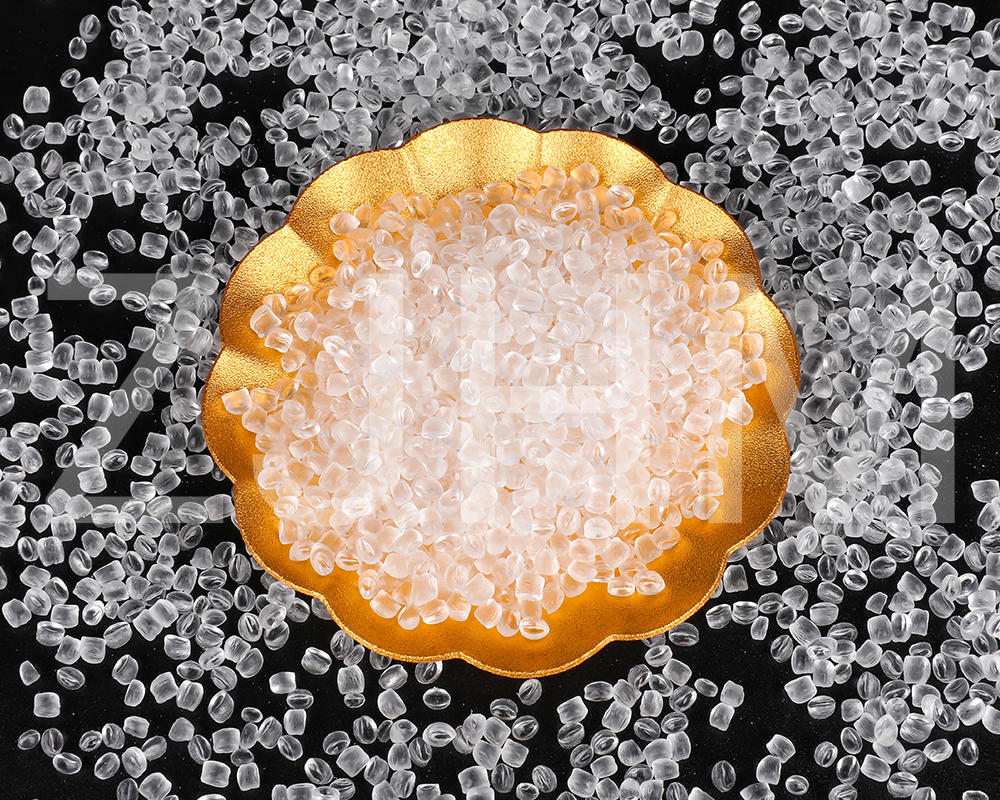

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate that is widely used in the manufacturing industry for its versatility, durability, and cost-effectiveness. EVA granules are the raw materials used in the production of a range of products, including footwear, packaging materials, solar cells, adhesives, and foam sheets.

One of the primary uses of EVA granules is in the footwear industry. EVA is used to make the midsole and outsole of athletic shoes, sandals, and other types of footwear. The material is preferred for its lightweight, shock-absorbing, and comfortable properties. EVA foam can also be molded into various shapes and sizes, making it ideal for creating custom-fit insoles and orthotics.

Another significant use of EVA granules is in the packaging industry. EVA foam sheets are widely used as protective packaging for delicate and fragile items. The foam provides cushioning and shock absorption, preventing damage during transit. EVA foam is also water-resistant and can be easily cut and shaped to fit the product being packaged.

EVA granules are also used in the production of solar cells. EVA is used as a encapsulant, which is a protective layer that covers the solar cells and helps to improve their efficiency. EVA is preferred for this application because of its excellent adhesion to both the solar cells and the glass cover.

In addition to these uses, EVA granules are also used in the production of adhesives, sealants, and coatings. EVA-based adhesives are known for their high strength and flexibility, making them ideal for bonding a variety of materials, including plastics, rubber, and metal. EVA sealants and coatings are used in the construction industry to provide a waterproof barrier and to improve the durability of structures.

What is the process for producing high-quality EVA granules for use in various applications?

EVA granules are an important material used in various applications, including footwear, sports equipment, automotive parts, and packaging. Ethylene-vinyl acetate (EVA) is a copolymer of ethylene and vinyl acetate that is known for its high elasticity, flexibility, and impact resistance. The production process for EVA granules involves several stages, including polymerization, extrusion, and pelletization, which are all critical for producing high-quality EVA granules.

The first stage in the production of EVA granules is polymerization. In this stage, ethylene and vinyl acetate monomers are combined in a reactor vessel and subjected to heat and pressure. A catalyst is also added to initiate the reaction, which causes the monomers to polymerize into EVA. The reaction is carefully controlled to ensure that the resulting EVA has the desired properties, such as a specific melt flow rate, density, and vinyl acetate content. The polymerization process can be carried out using different methods, including solution polymerization, suspension polymerization, and gas-phase polymerization.

Once the EVA is polymerized, it is extruded into a continuous sheet using an extruder machine. The extruder machine consists of a screw that melts the EVA and pushes it through a die to create a continuous sheet. The temperature and pressure of the extruder are carefully controlled to ensure that the EVA sheet has a uniform thickness and a smooth surface. The extruded EVA sheet is then cooled and cut into small pellets, which are referred to as EVA granules.

English

English

Español

Español