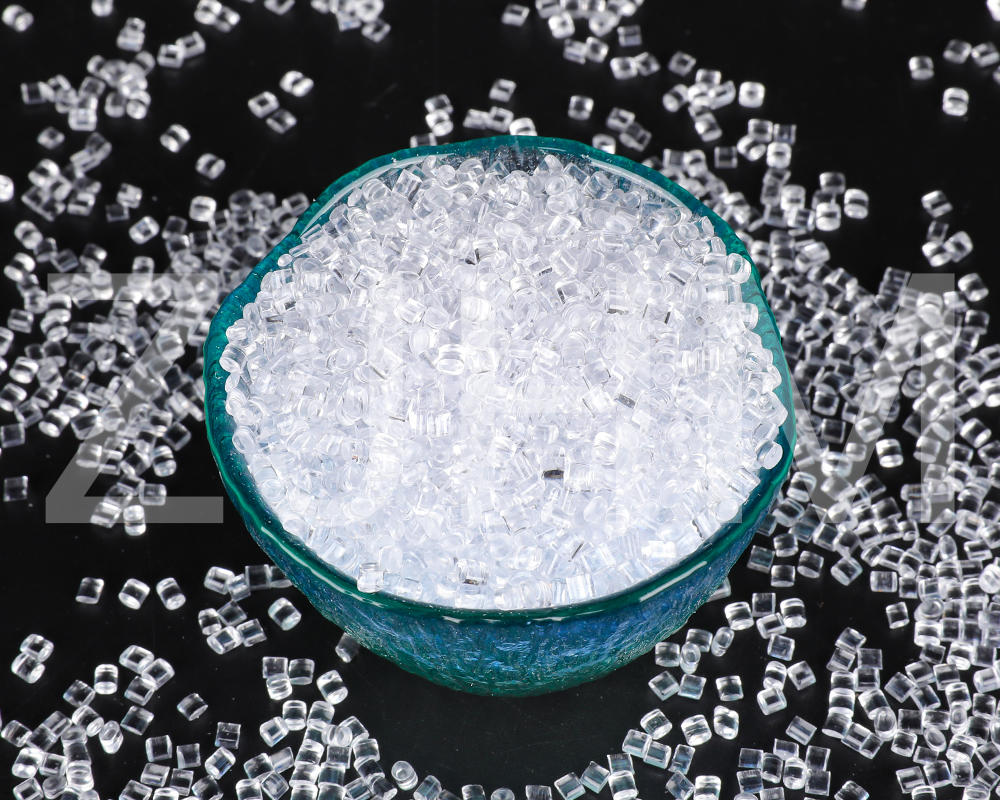

In today’s fast-paced industrial landscape, materials that deliver both performance and economy are invaluable. Among the myriad of thermoplastics available, GPPS (General Purpose Polystyrene) granules stand out as a cornerstone for countless manufacturing applications. But what exactly propels these translucent pellets to such prominence?

GPPS granules are a rigid, amorphous polymer made from styrene monomer through a process of free-radical polymerization. What distinguishes GPPS is its striking clarity, high gloss, and ease of processing — attributes that make it indispensable for a broad spectrum of industries. Whether it’s in food packaging, electronics housings, disposable cutlery, or household appliances, GPPS brings a dependable consistency that engineers and designers can trust.

One of the foremost advantages of GPPS lies in its aesthetic appeal. With a naturally glass-like appearance, GPPS offers a visual purity that is hard to replicate. For applications where clarity and surface finish matter — think CD cases, transparent containers, or light diffusers — GPPS is the material of choice. Its high surface luster elevates the look and feel of finished products, providing not just functionality but consumer appeal.

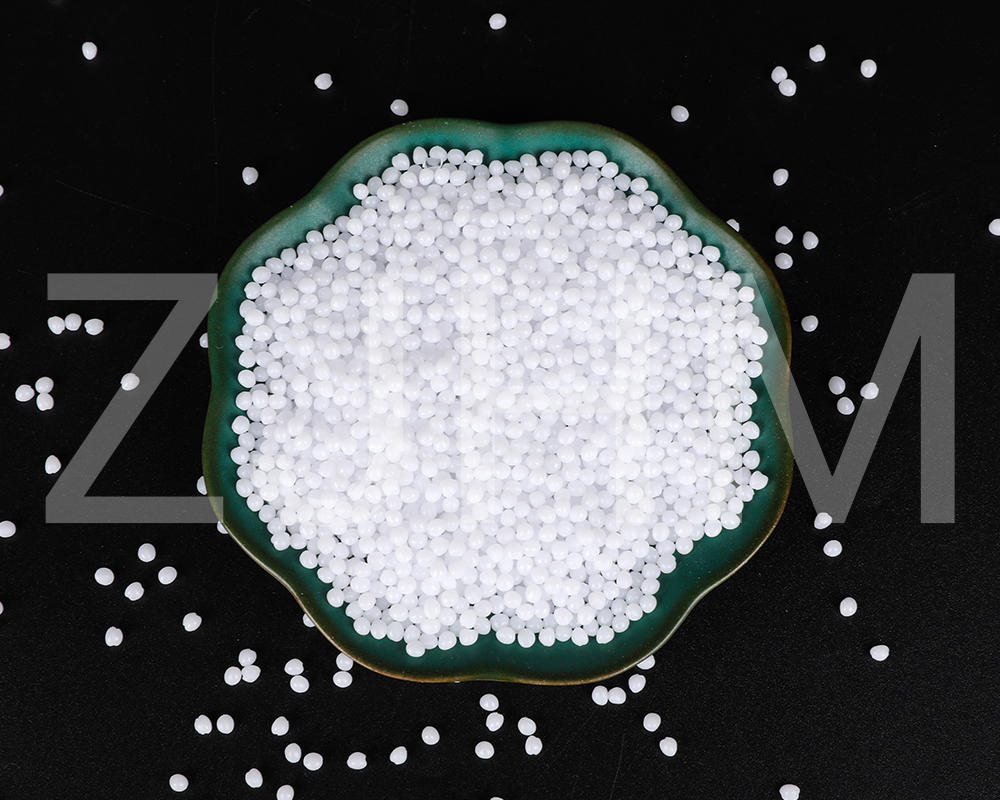

Beyond aesthetics, GPPS is prized for its processability. It flows easily during molding and extrusion, enabling high-speed manufacturing with minimal defects. This not only boosts production efficiency but also lowers operational costs. GPPS can be thermoformed, injection molded, or extruded, adapting to the demands of different product designs with remarkable flexibility.

But GPPS is more than just easy to mold. Its dimensional stability and rigidity make it reliable for precision parts that require structural integrity without the added cost of engineering plastics. Though it lacks impact resistance compared to HIPS (High Impact Polystyrene), it compensates with stiffness and a cost-effective profile that suits non-load-bearing applications perfectly.

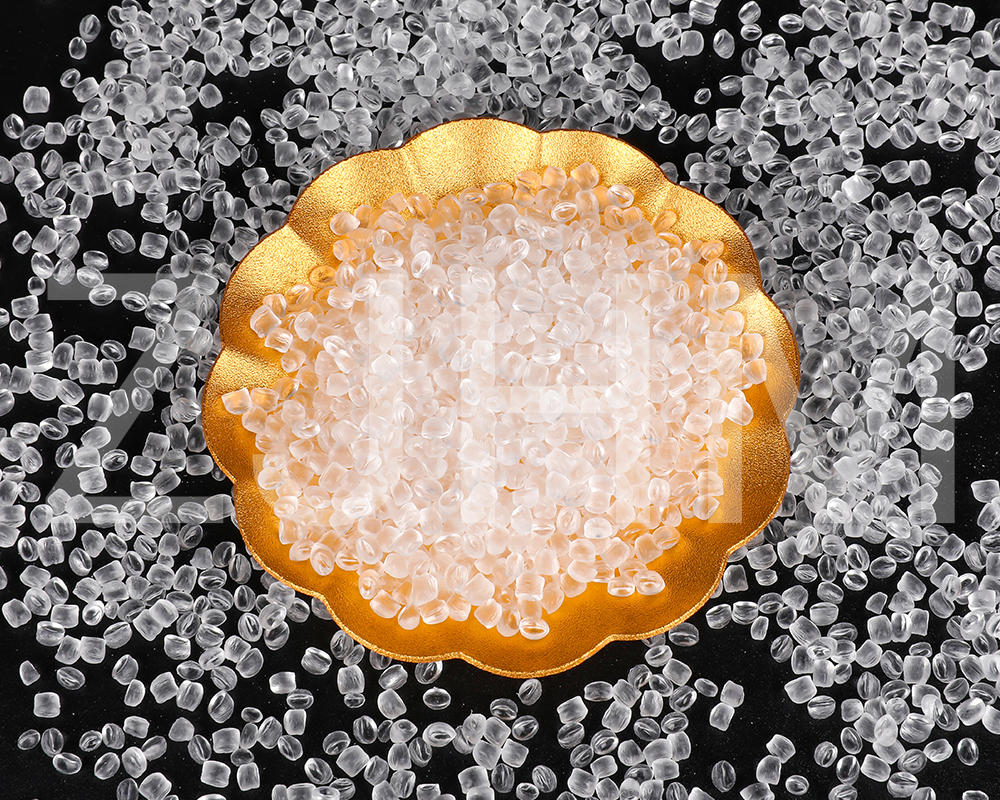

Environmental sustainability is another reason GPPS is garnering attention. As the push for circular economies and recyclability intensifies, GPPS offers a relatively low environmental footprint. It can be mechanically recycled and reintroduced into production lines, aligning with modern sustainability goals without compromising quality.

Let’s not overlook cost. In a competitive marketplace, affordability can be a decisive factor. GPPS is economically viable, offering manufacturers a high-performance polymer at a lower price point compared to alternatives like acrylic or polycarbonate. This makes it ideal for high-volume, cost-sensitive markets without sacrificing visual or structural integrity.

GPPS granules are not merely a material; they are a strategic solution for manufacturers seeking clarity, formability, and cost efficiency. As industries evolve and consumer expectations rise, GPPS continues to prove its worth — a quiet yet powerful enabler behind many of the everyday items we often overlook.

English

English

Español

Español

+86-0571-61070797

+86-0571-61070797