ABS granules have become a cornerstone in the world of industrial production, revolutionizing numerous sectors with their versatility and superior qualities. As manufacturers continue to seek more efficient, cost-effective, and high-performance materials, ABS granules have garnered widespread recognition for their remarkable properties. But what exactly makes these granules so indispensable in modern manufacturing?

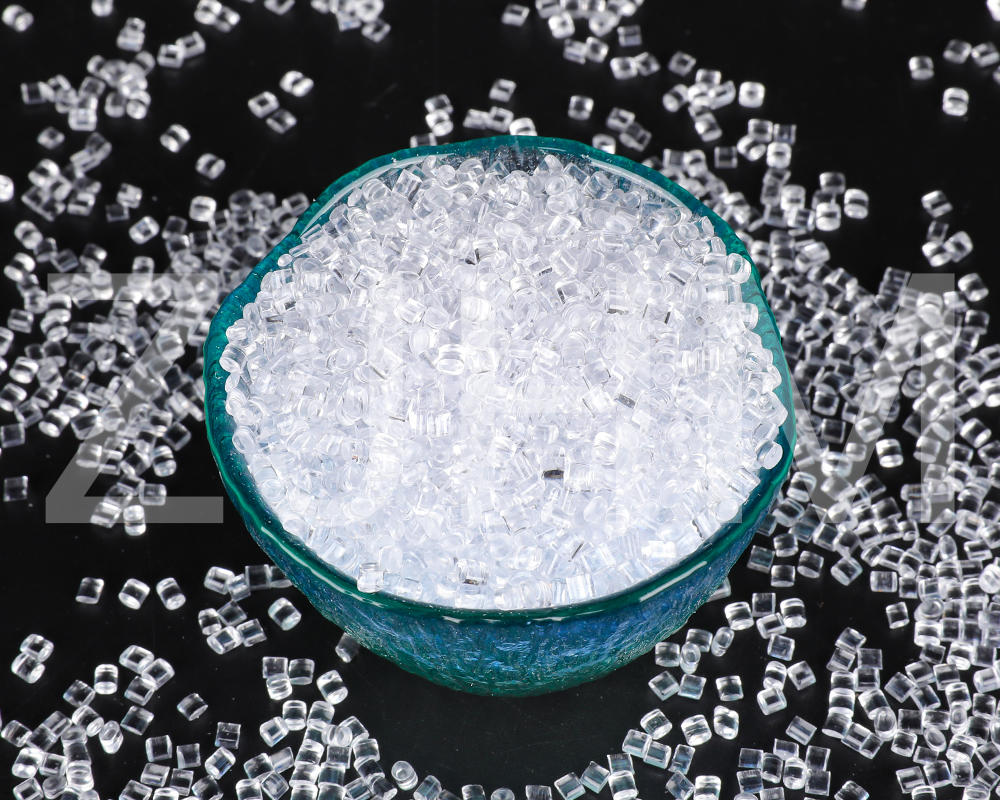

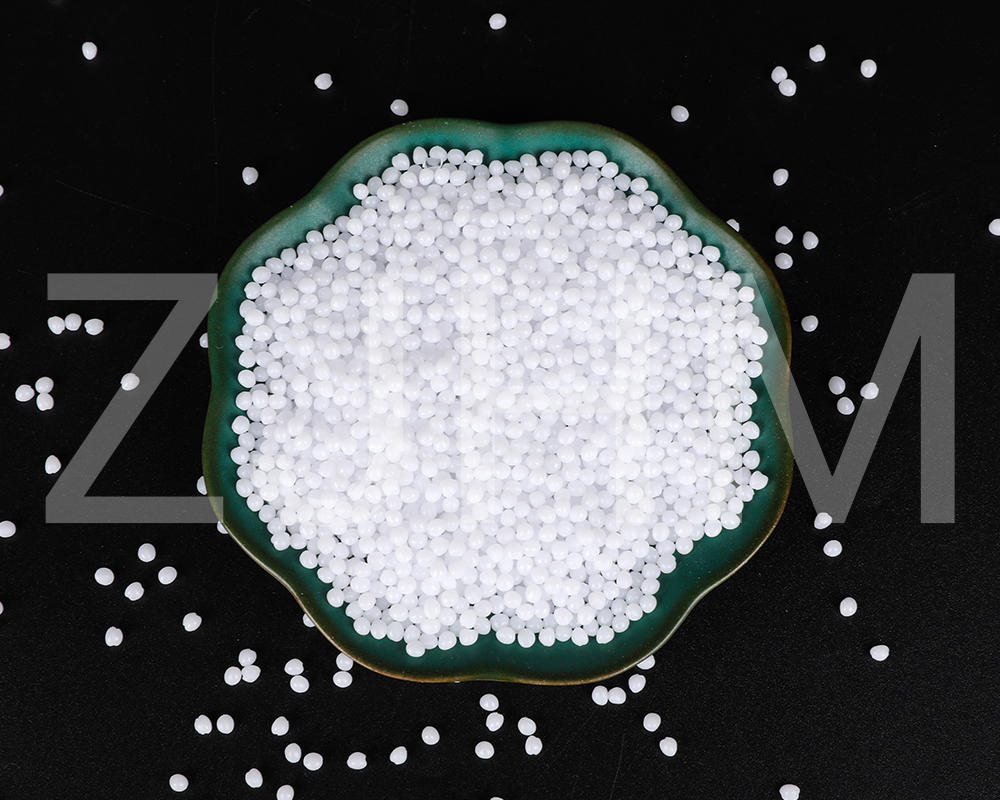

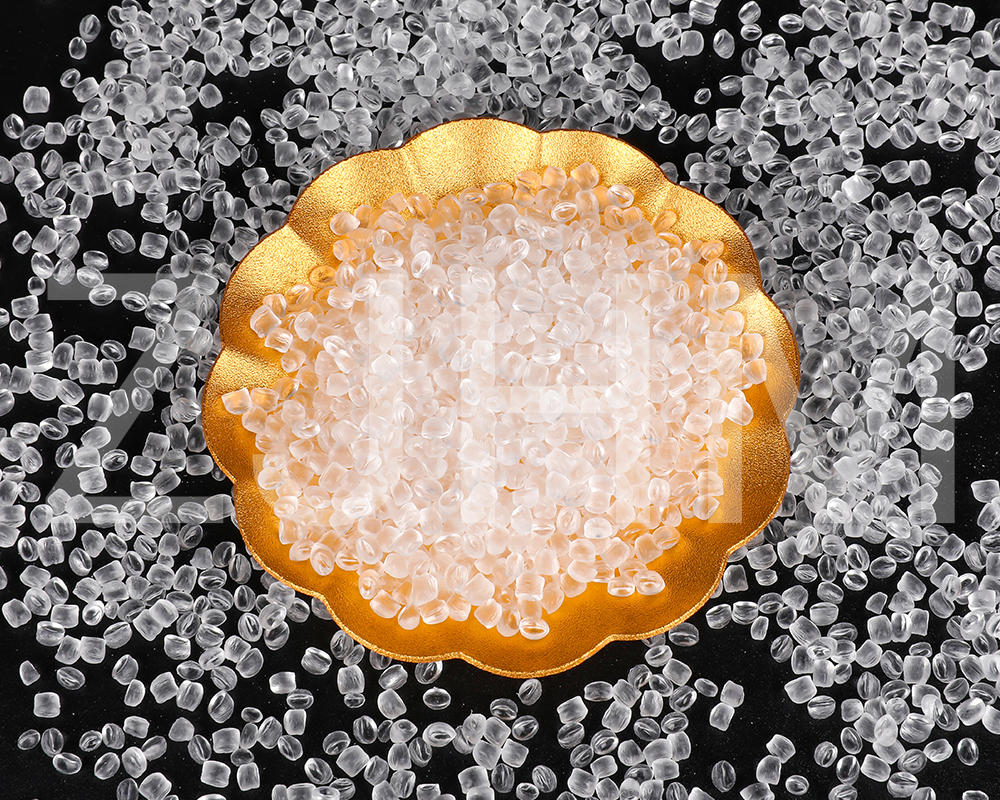

ABS granules are the result of a polymerization process that combines three distinct monomers: acrylonitrile, butadiene, and styrene. This trifecta of materials contributes to the granules' exceptional combination of strength, durability, and flexibility, making them suitable for a broad range of applications. Their inherent resistance to impact, temperature fluctuations, and harsh chemicals ensures that ABS stands out in industries where high-performance materials are required.

Unmatched Versatility Across Industries

From automotive parts to consumer electronics, ABS granules are renowned for their adaptability. In the automotive sector, they are frequently used to produce robust interior components, including dashboards, trim, and bumpers. The granules provide both the strength required for safety and the aesthetic finish demanded by modern vehicle design. Likewise, the electronics industry relies heavily on ABS for manufacturing durable casings and housings for devices such as computers, televisions, and smartphones, where both function and design are of paramount importance.

In addition to these industries, ABS granules have a strong presence in the production of household goods, medical devices, and even toys. The granules’ ability to be easily molded and colored enables manufacturers to create products in an array of shapes, sizes, and finishes, all while maintaining consistent quality.

A Cost-Effective Choice for Manufacturers

What truly sets ABS apart from other materials is its cost-effectiveness. The production of ABS granules is relatively inexpensive compared to other high-performance plastics, making it an attractive option for manufacturers looking to balance quality with cost. With its wide availability and ease of processing, ABS granules offer an ideal solution for large-scale production without compromising on product integrity.

The granules can be easily processed through injection molding, extrusion, and thermoforming, which streamlines the manufacturing process, reduces lead times, and lowers overall production costs. The ease of recycling ABS further enhances its appeal, as companies are increasingly adopting sustainable practices.

Why Choose ABS Granules for Your Manufacturing Needs?

The question is not just about why ABS granules are so widely used but rather how they can elevate the quality and efficiency of your manufacturing processes. Whether you are producing components for the automotive industry, crafting consumer products, or developing cutting-edge electronics, ABS granules offer an unmatched balance of performance, versatility, and cost-effectiveness.

As industries evolve and demand continues to rise for high-quality, durable products, ABS granules remain an indispensable material for modern manufacturing. Their ability to meet the diverse needs of various sectors, combined with their superior physical properties and economic advantages, ensures that ABS will continue to play a critical role in the future of industrial production.

English

English

Español

Español

+86-0571-61070797

+86-0571-61070797