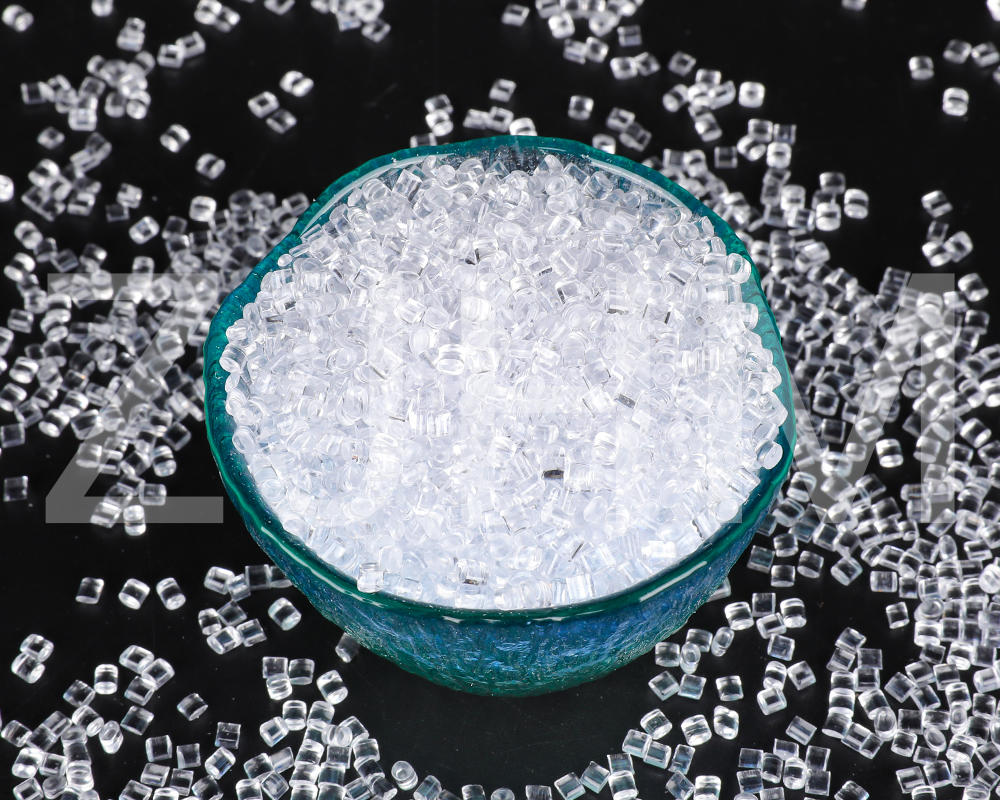

High-Density Polyethylene (HDPE) granules stand as a cornerstone of the polymer industry, silently powering a multitude of applications that shape our daily lives. These compact, resilient pellets are more than just raw materials—they are the foundation of innovation in packaging, construction, agriculture, and countless industrial domains.

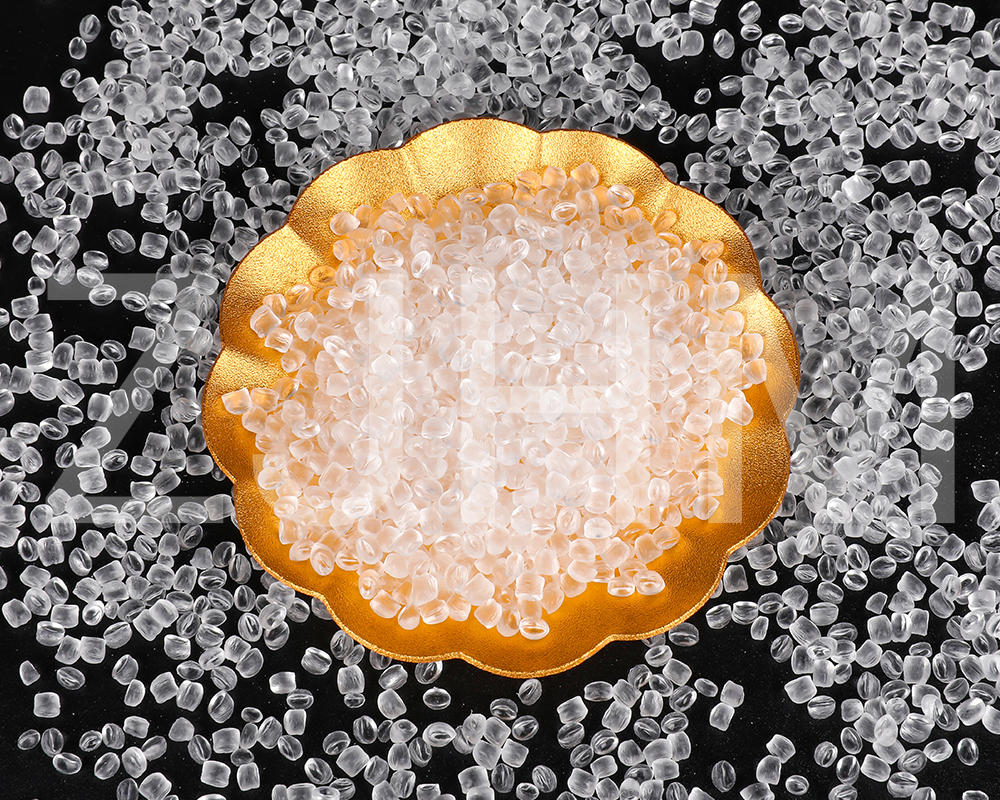

HDPE granules are synthesized through the polymerization of ethylene, resulting in a thermoplastic polymer characterized by high strength-to-density ratio. The outcome? A material that is lightweight yet immensely durable, chemically resistant, and cost-effective. From heavy-duty containers to precision-engineered piping systems, HDPE granules offer the structural integrity and performance manufacturers demand in today’s competitive market.

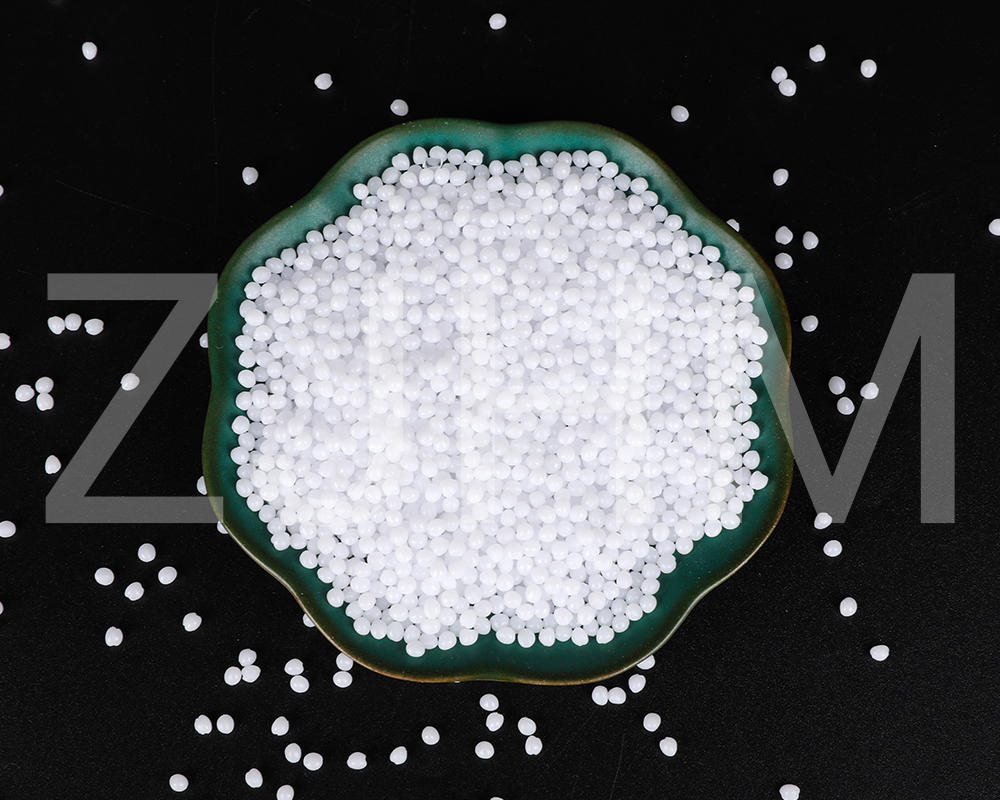

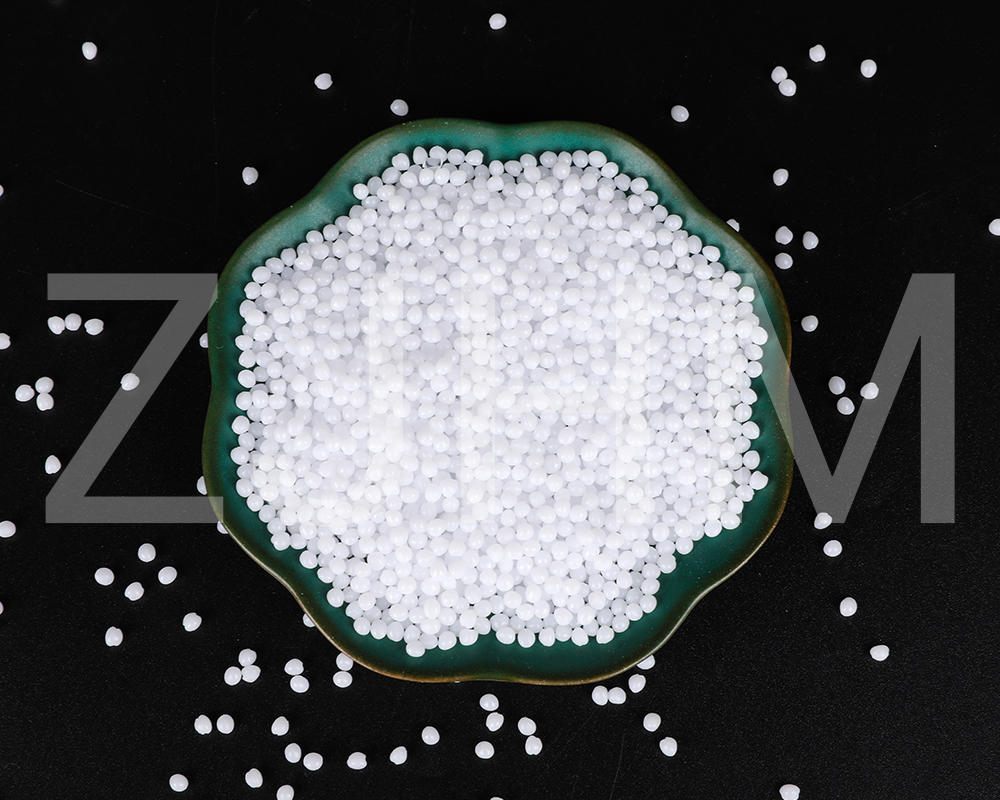

One of the most compelling attributes of HDPE granules lies in their adaptability. Available in virgin and recycled forms, they cater to both sustainability goals and stringent quality standards. Virgin granules are the go-to for applications requiring uncompromised purity—think pharmaceutical packaging or potable water pipes. Recycled granules, on the other hand, are rapidly gaining traction among eco-conscious manufacturers aiming to reduce environmental impact without sacrificing utility.

Industries gravitate toward HDPE granules not just for their mechanical prowess, but also for their processing ease. Whether through injection molding, blow molding, or extrusion, HDPE granules melt into form with efficiency and precision. This thermoplastic’s low melting point simplifies manufacturing cycles and reduces energy consumption—an edge in both operational cost and carbon footprint.

Chemically inert and impervious to most solvents, HDPE granules exhibit exceptional resistance to UV rays, corrosion, and moisture. This makes them ideal for outdoor applications such as irrigation systems, garden furniture, and chemical storage solutions. Their ability to endure fluctuating weather conditions without degradation enhances their appeal in global markets where environmental extremes are the norm rather than the exception.

Aesthetically, HDPE granules offer versatility in coloration and finish, empowering designers to balance function with form. Whether matte or glossy, pigmented or natural, the customization potential is limitless. This versatility, combined with mechanical robustness, positions HDPE as a material of choice in sectors where brand identity and product resilience must coalesce.

As global demand for sustainable and high-performance materials accelerates, HDPE granules continue to demonstrate their relevance. Advances in polymer science are further enhancing the recyclability and functional properties of these granules, reinforcing their role in a circular economy. Manufacturers seeking materials that marry durability with environmental accountability are increasingly turning to HDPE for answers.

HDPE granules are more than mere raw materials—they are enablers of progress. Their intrinsic properties, coupled with remarkable processing versatility, make them indispensable in today’s manufacturing ecosystem. As industries evolve and sustainability becomes paramount, HDPE granules will undoubtedly remain at the forefront—silent, robust, and essential.

English

English

Español

Español

+86-0571-61070797

+86-0571-61070797