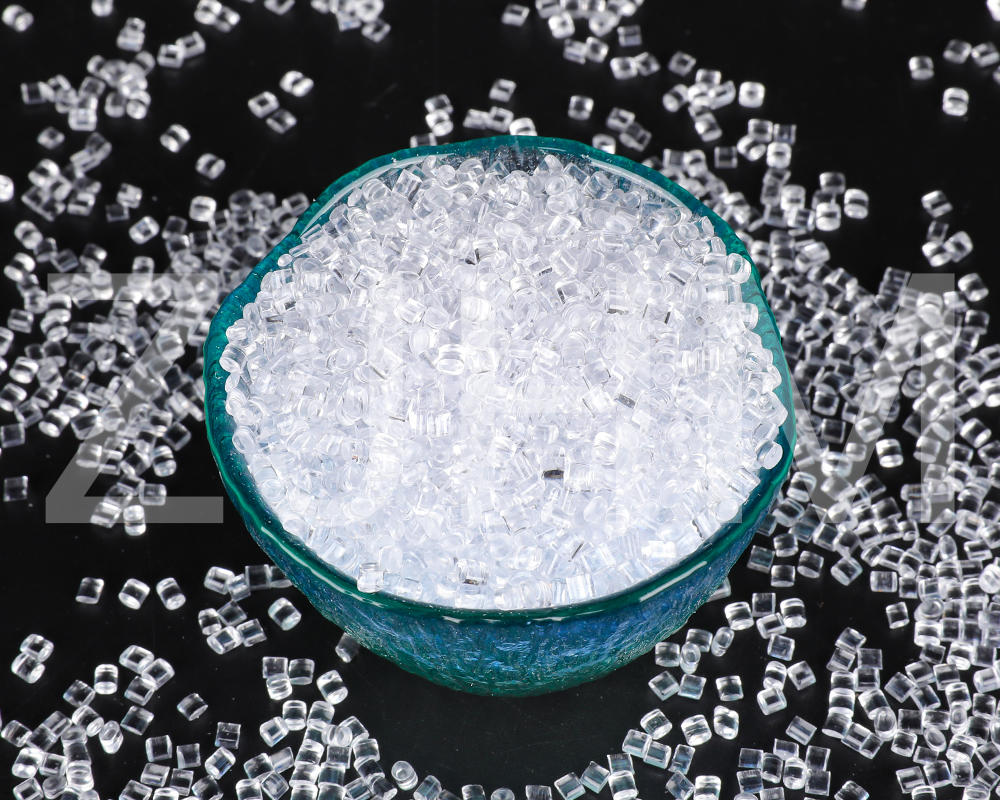

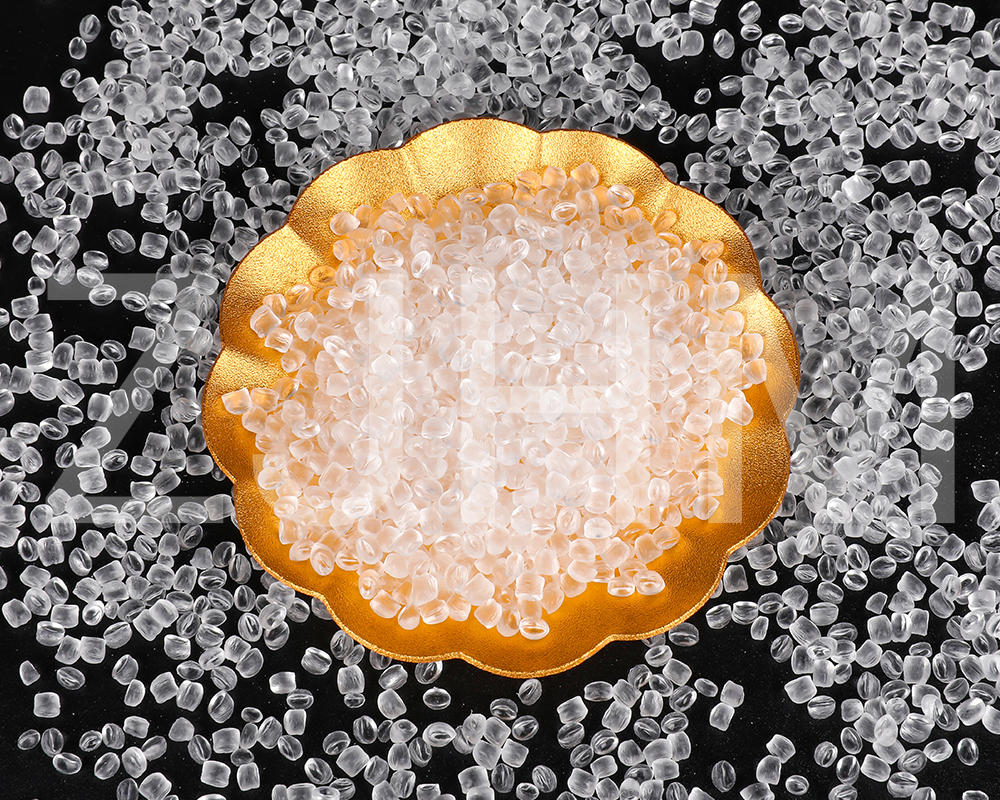

Polystyrene GPPS granules are the unsung workhorses behind a multitude of modern-day applications. Revered for their crystal clarity, rigidity, and ease of processing, GPPS granules offer a unique synthesis of visual appeal and mechanical reliability. As industries push the boundaries of product aesthetics and functionality, these thermoplastic beads remain integral to delivering consistent, high-quality results across a spectrum of end-use scenarios.

A Material with Clarity and Character

Unlike its high-impact cousin, GPPS is prized for its unalloyed transparency and gloss. This amorphous polymer does not crystallize, making it an ideal candidate for products where optical clarity is paramount. Retail packaging, laboratory ware, and disposable consumer goods often rely on GPPS for this very reason—it allows designers to showcase the contents within while maintaining structural elegance.

Beyond aesthetics, GPPS granules deliver outstanding dimensional stability. They resist warping under moderate stress and maintain their shape with remarkable fidelity. This makes them exceptionally suitable for precision molding operations where geometric accuracy is not a luxury but a necessity.

Mechanical and Thermal Profile

From a performance standpoint, GPPS holds its own. It boasts a relatively high tensile modulus, giving it a firm, inflexible nature. The granules process easily at moderate temperatures, making them well-suited to injection molding, extrusion, and thermoforming. Once molded, products retain their shape and integrity even when subjected to typical handling and operational stresses.

Thermally, GPPS demonstrates a moderate heat resistance. While not designed for high-heat applications, it performs reliably within its operational range—typically up to 100°C. This thermal behavior is more than adequate for a wide range of packaging and consumer product applications.

Applications That Span Industries

GPPS granules find homes in industries ranging from food and beverage to electronics. In food packaging, they are molded into containers, cups, and trays—each benefiting from the material’s inertness and compliance with food safety regulations. In consumer electronics, GPPS serves in housing components that demand both form and function. Even in the arts and crafts sector, where visual impact is crucial, GPPS provides the clarity and rigidity artists seek.

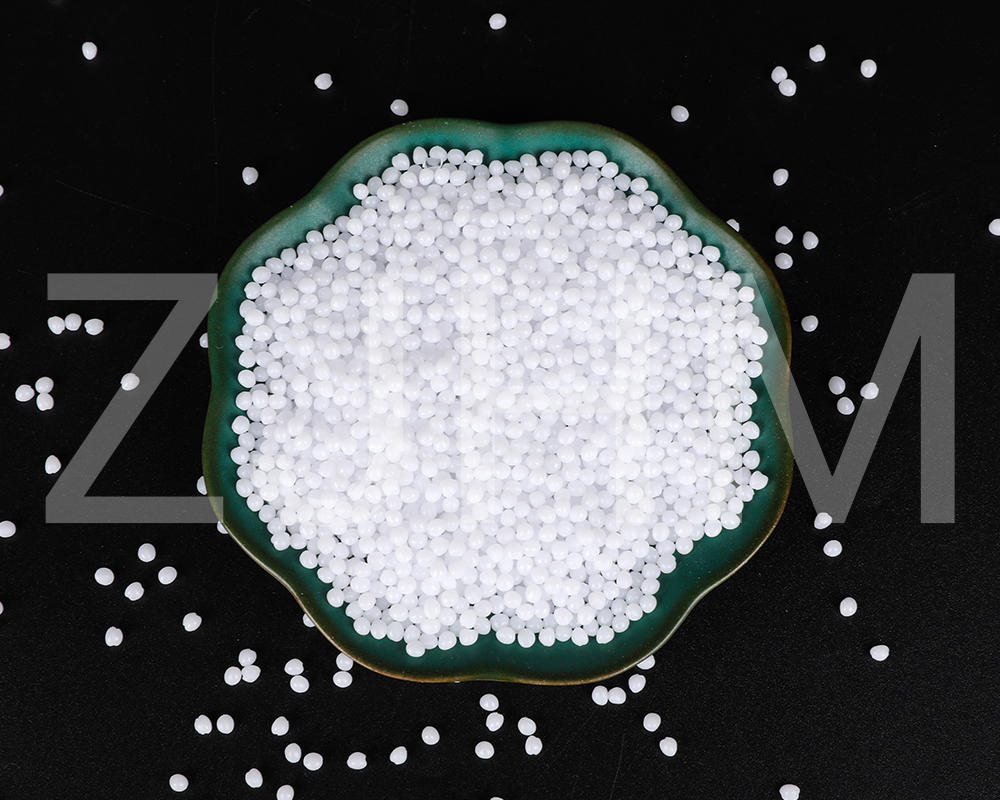

Its compatibility with coloring agents and additives allows for extensive customization. Whether it's through vibrant hues or UV stabilizers, GPPS granules can be tailored to meet the precise demands of a given product environment.

Economic and Environmental Considerations

Economically, GPPS granules offer exceptional value. Their widespread availability, ease of processing, and minimal waste during manufacturing contribute to low per-unit costs—an attractive proposition for mass production.

On the environmental front, GPPS is 100% recyclable. Although not biodegradable, it can be repurposed into secondary products, thereby extending its lifecycle. Innovations in recycling technology continue to improve the reusability and environmental footprint of GPPS-based materials.

Choosing the Right Supplier Matters

The integrity of a final product begins with the quality of its raw materials. When sourcing GPPS granules, consistency in pellet size, purity, and melt flow index can have a significant downstream impact. Reliable suppliers offer not just materials but also technical expertise—guiding clients in selecting the right formulation for their specific application.

Polystyrene GPPS granules offer a harmonious blend of aesthetics, performance, and economic efficiency. Their role in shaping the consumer landscape is both quiet and profound. Whether you’re packaging a product, crafting a component, or designing for mass manufacturing, GPPS is a material that delivers clarity—not just in appearance, but in purpose.

English

English

Español

Español

+86-0571-61070797

+86-0571-61070797