In the realm of modern industry, few materials have wielded as transformative an influence as plastic granules. These unassuming pellets—uniform, compact, and engineered to exacting standards—are the raw material that fuels an astonishing range of products. From household goods to high-performance components in aerospace and medicine, plastic granules serve as the foundational building blocks of polymer-based innovation.

What Are Plastic Granules?

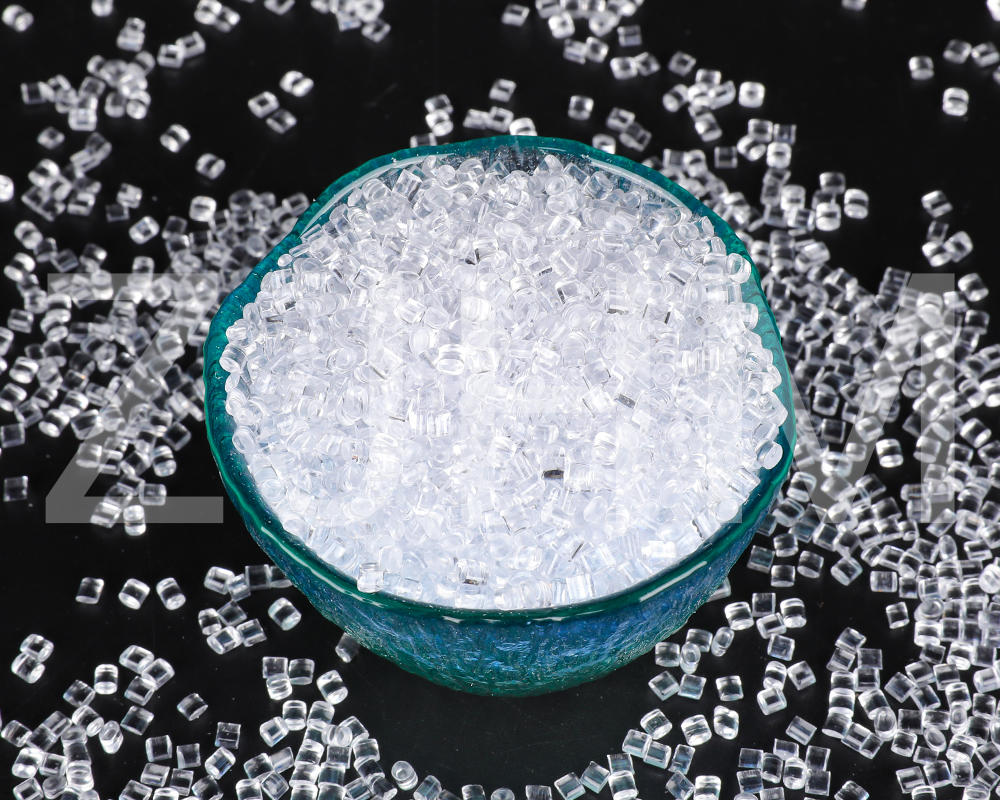

Plastic granules are small, bead-like particles made of synthetic or semi-synthetic polymer compounds. Produced via polymerization or polycondensation processes, these granules are meticulously designed to exhibit specific physical, chemical, and mechanical characteristics. They are the essential intermediate form before plastics are molded, extruded, or formed into final products.

Granules come in a spectrum of polymer families: polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), polyethylene terephthalate (PET), and more specialized engineering plastics such as polyamide (PA), polycarbonate (PC), and acrylonitrile butadiene styrene (ABS). Each type serves a niche, answering the unique demands of diverse applications—from flexible packaging films to impact-resistant automotive panels.

The Manufacturing Process

Plastic granule production begins with the synthesis of base polymers through complex chemical reactions. Once synthesized, the resin is melted and filtered, then subjected to high-pressure extrusion through a die plate. As the molten polymer emerges, it is rapidly cooled and cut into uniformly sized pellets.

The precision in granule size, moisture content, and melt flow index is not incidental—it’s critical. Uniformity ensures that when the granules are fed into machines for injection molding, blow molding, or extrusion, the results are consistent, stable, and high-quality. In essence, well-manufactured granules equate to predictable performance.

Types and Applications

Each plastic granule formulation is engineered with a purpose.

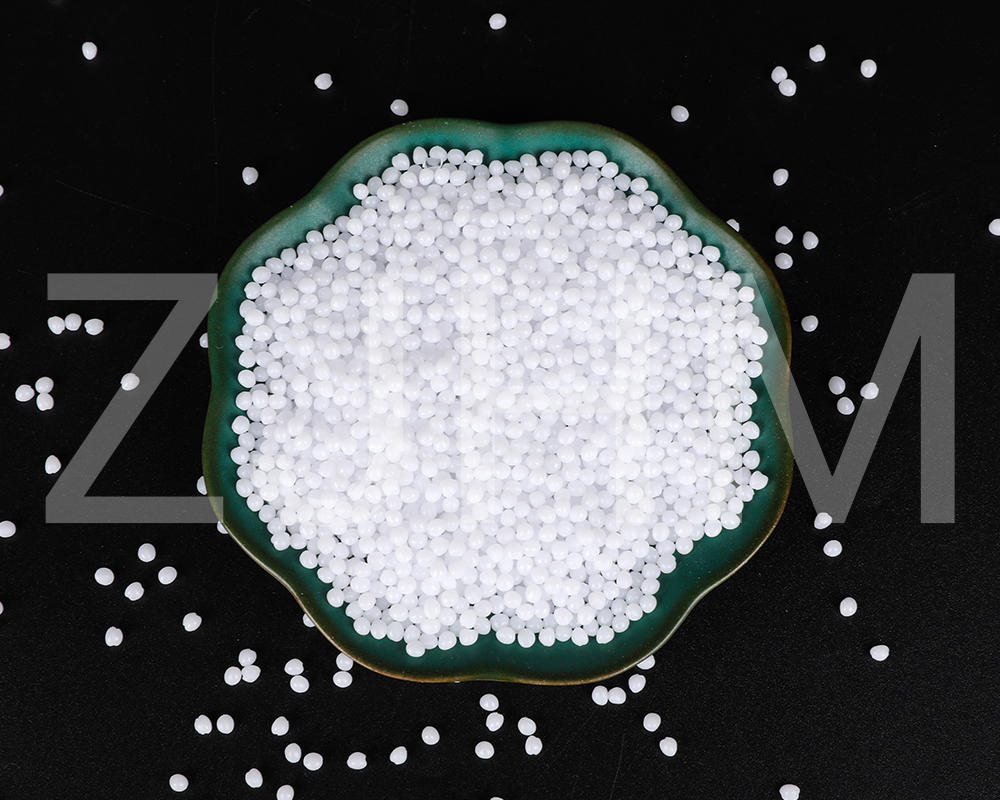

Polyethylene (PE) granules, known for their flexibility and chemical resistance, are widely used in films, containers, and piping systems.

Polypropylene (PP) granules offer durability and fatigue resistance, making them ideal for automotive parts, textiles, and consumer products.

Polyvinyl Chloride (PVC) granules are preferred for their flame-retardant properties and are extensively used in construction materials and electrical insulation.

Engineering plastics like PC, PA, and ABS bring high strength and thermal stability, often used in electronics, mechanical parts, and precision instruments.

Color, additive content, and recyclability further diversify granule types. UV stabilizers, flame retardants, anti-static agents, and color masterbatches are often blended to tailor properties to specific operational environments.

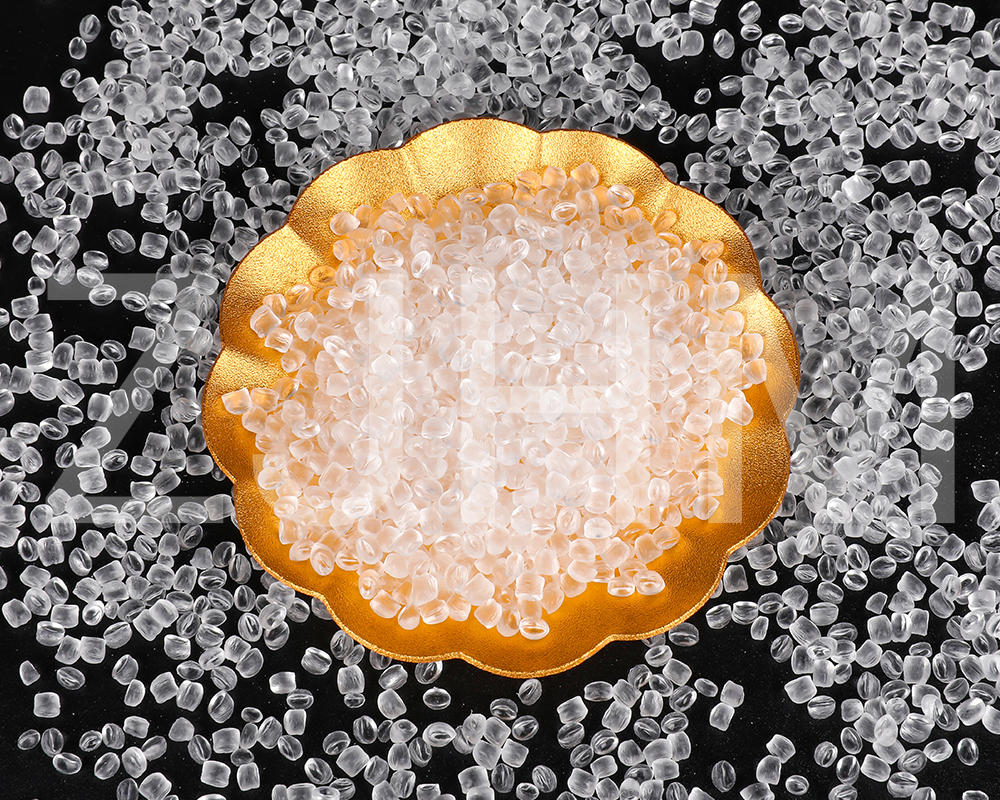

The Role of Recycled Granules

With sustainability moving from buzzword to business imperative, recycled plastic granules are no longer an afterthought—they’re a necessity. Post-consumer and post-industrial plastics are cleaned, shredded, re-pelletized, and reintegrated into production cycles. Modern granule reprocessing ensures performance is maintained, reducing dependency on virgin plastics and minimizing environmental impact.

Recycled granules are now commonly used in everything from packaging and containers to construction panels and even automotive components. Advanced sorting and refining technologies have made it possible to close the loop without compromising on performance.

Why Granule Quality Matters

Precision is paramount. Impurities, moisture content, or inconsistent sizing can wreak havoc in high-speed manufacturing environments. Poor-quality granules result in surface defects, mechanical weakness, and reduced product lifespan. That’s why reputable suppliers adhere to stringent quality control standards—ISO certifications, RoHS compliance, and traceability protocols are non-negotiable.

For manufacturers, the choice of granule supplier is a strategic decision. It affects product quality, production efficiency, and regulatory compliance. It’s not just about the granules—it’s about the consistency, the logistics, the reliability of delivery, and the depth of technical support.

Plastic granules are not just raw materials—they are the DNA of polymer-based manufacturing. Their versatility, adaptability, and critical role in shaping the modern world make them an indispensable element of industrial progress. As innovation marches forward and sustainability redefines priorities, the evolution of plastic granules continues to shape industries, one pellet at a time.

English

English

Español

Español

+86-0571-61070797

+86-0571-61070797