In the expansive landscape of polymer materials, Low-Density Polyethylene (LDPE) granules hold a distinctive position. Revered for their flexibility, chemical resistance, and transparency, LDPE granules serve as the backbone of a multitude of everyday applications. From packaging films to cable insulation, these thermoplastic marvels are quietly indispensable to both industrial operations and consumer products.

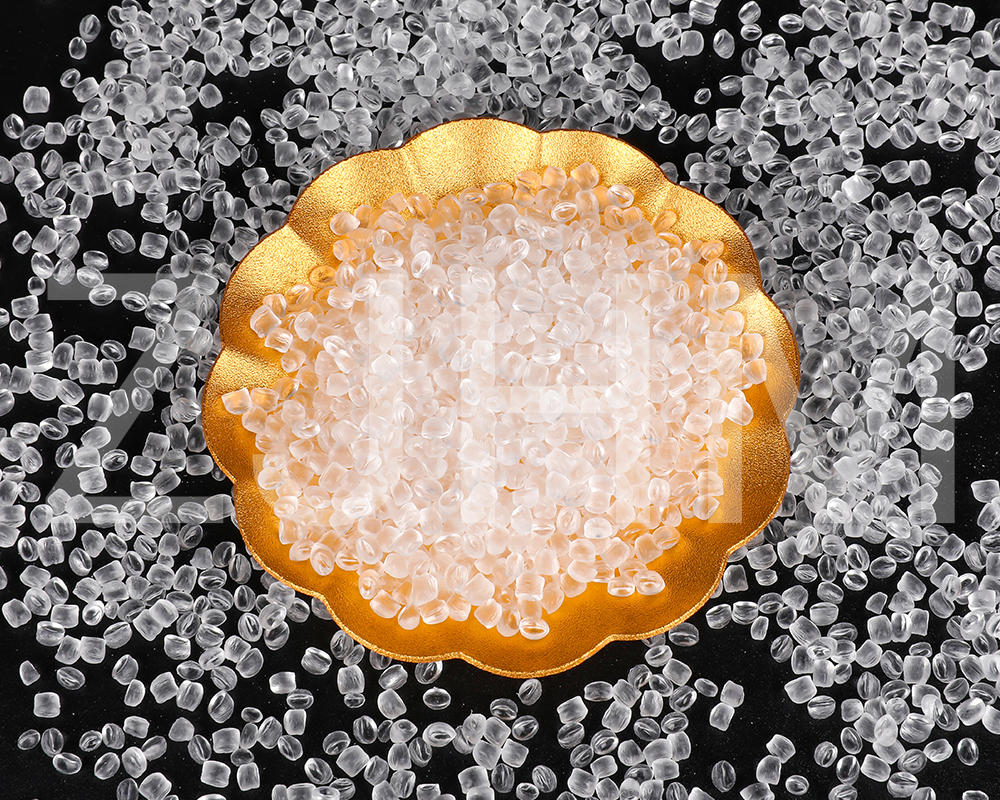

LDPE granules are characterized by their low-density molecular structure. Unlike their high-density counterparts, LDPE's branched polymer chains allow for a pliable and resilient composition. This unique structure yields a material that is not only soft and lightweight but also highly durable—capable of withstanding mechanical stress without cracking or tearing.

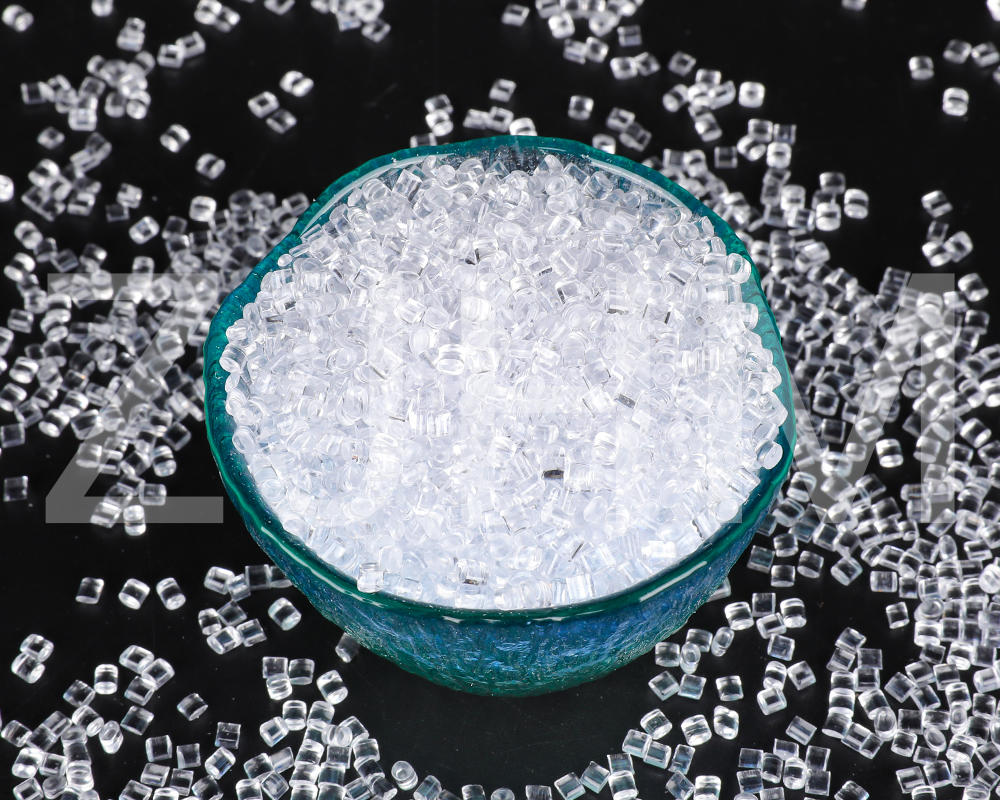

Manufactured through the polymerization of ethylene gas under high pressure, LDPE granules emerge as small, uniform pellets. Their consistent shape and size streamline the production process, making them a favorite among extrusion and injection molding facilities. Whether in the creation of thin-film grocery bags or intricate molded parts, these granules offer manufacturers a material that is both reliable and versatile.

One of LDPE's most prized qualities is its resistance to moisture and chemicals. This makes it an optimal choice for food-grade applications, as it safeguards contents without leaching or degradation. The packaging industry, in particular, relies heavily on LDPE for its ability to create protective, see-through films that are both functional and aesthetically appealing.

Additionally, LDPE granules possess excellent electrical insulating properties, making them ideal for wire and cable applications. Their ability to resist environmental factors, including UV rays and corrosive elements, further expands their utility across a wide range of industries—from agriculture to healthcare.

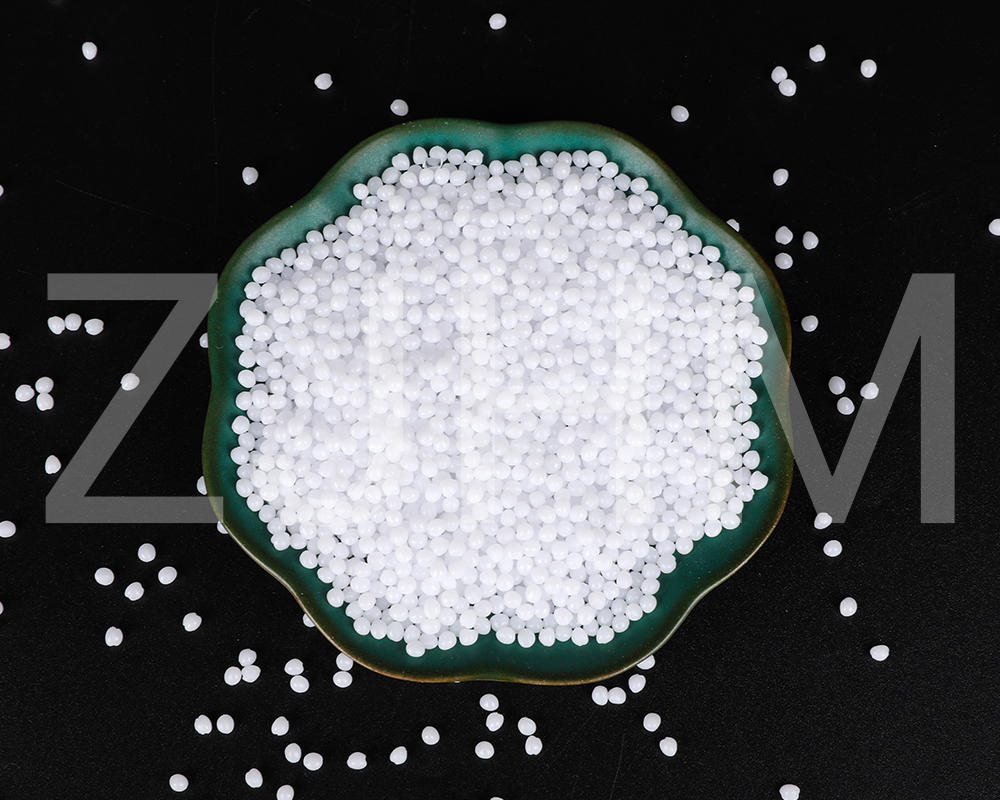

The recyclability of LDPE is another significant advantage, although it comes with nuances. While LDPE is technically recyclable, its recovery rate lags behind other plastics due to collection and contamination challenges. However, as sustainability initiatives gain momentum globally, efforts to reprocess LDPE waste into reusable granules are gaining traction. These recycled LDPE granules offer comparable performance in non-critical applications, contributing to circular economy goals without compromising functionality.

For manufacturers and suppliers, the quality of LDPE granules is paramount. Purity, melt flow index, and density are closely monitored to ensure consistency across batches. A single deviation in material properties can result in production inefficiencies or compromised product performance. As such, sourcing LDPE granules from reputable producers is not just advisable—it’s essential.

In a world increasingly shaped by lightweight, adaptable materials, LDPE granules stand out as a quiet yet powerful contributor. Their role may often go unnoticed by the end-user, but to the industries that rely on their properties, LDPE granules are nothing short of foundational. From safeguarding goods to powering infrastructure, their value is enduring—and evolving.

English

English

Español

Español

+86-0571-61070797

+86-0571-61070797